General remarks

Reshoring props, concrete technology and stripping out

|

|

Follow the directions in the Calculation Guide entitled 'Stripping out formwork from floors in building construction', and/or ask your Doka technician. |

.

When is the best time to strip out the formwork?

The concrete strength needed before the formwork can be stripped out will depend upon the load factor α. This can be read off from the following table.

.

Load factor α

This is calculated by:

|

α = |

DLconcrete + LLconstruction state |

|

DLconcrete + DLfinishing + LLfinal state |

|

Slab thickness 'd' [m] |

Dead load DLconcrete [kN/m2] |

Load factor α |

|||

|---|---|---|---|---|---|

|

2.00 kN/m2 |

3.00 kN/m2 |

4.00 kN/m2 |

5.00 kN/m2 |

||

|

0.14 |

3.50 |

0.67 |

0.59 |

0.53 |

0.48 |

|

0.16 |

4.00 |

0.69 |

0.61 |

0.55 |

0.50 |

|

0.18 |

4.50 |

0.71 |

0.63 |

0.57 |

0.52 |

|

0.20 |

5.00 |

0.72 |

0.65 |

0.59 |

0.54 |

|

0.22 |

5.50 |

0.74 |

0.67 |

0.61 |

0.56 |

|

0.25 |

6.25 |

0.76 |

0.69 |

0.63 |

0.58 |

|

0.30 |

7.50 |

0.78 |

0.72 |

0.67 |

0.62 |

|

0.35 |

8.75 |

0.80 |

0.75 |

0.69 |

0.65 |

Valid for a finishing-load DLfinishing = 2.00 kN/m2 and a live load in the early-stripped state of LLconstruction state = 1.50 kN/m2

DLconcrete: calculated with γconcrete = 25 kN/m3

DLfinishing: load for floor finish, etc.

Example: Slab thickness 0.20 m with a final live load of 5.00 kN/m2 results in a load factor α of 0.54.

This means that formwork removal / stress-release can take place once the concrete has reached 54% of its 28-day strength. The load-bearing capacity will then correspond to that of the finished structure.

|

|

NOTICE If the floor props are not stress-relieved, meaning that the slab has not been activated, then the props will remain loaded with the dead weight of the floor-slab. When the floor above is concreted, this may lead to a doubling of the load that is being applied to the floor props. The floor props are not designed to cope with such an overload, and the result may be damage to the formwork, the floor props and the structure. |

.

Why put up reshoring props after stripping out the formwork?

After the formwork has been stripped and the slab has been stress-relieved or dismantled, the slab is able to bear its dead load and live loads resulting from the construction state, but not the concreting loads from subsequent floor-slabs.

The temporary reshoring serves to support the floor-slab and distribute the concreting loads across several floors.

.

Positioning the reshoring props correctly

Reshoring props have the job of spreading loads between the new floor-slab and the floor beneath it. The load distribution will depend on the relationship between these two floor-slabs and their rigidity.

|

|

NOTICE Ask an expert! As a rule, the question of using reshoring props should be referred to the responsible experts, regardless of the information given above. Observe all local standards and regulations! |

.

Deflection of the new concrete

The concrete's modulus of elasticity develops faster than compressive strength. At 60 % of its compressive strength fck, the concrete has already reached approximately 90% of its modulus of elasticity Ec(28).

The increase in the elastic deformation taking place in the new concrete is thus only negligible.

The creep deformation, which only finally ceases after several years, is several times more than the elastic deformation.

Early striking – e.g. after 3 days instead of 28 – thus only leads to an increase in the total deformation of less than 5%.

The part of this deformation accounted for by creep deformation, however, may be anything between 50% and 100% of the standard value, due to such variable influences as the strength of the aggregates, and the atmospheric humidity. This means that the total deflection of the floor-slab is practically independent of the time at which the formwork was struck.

.

Cracks in new concrete

The bonding strength between the reinforcement steel and the concrete develops more rapidly in the new concrete than does its compressive strength. This means that early stripping does not have any negative influence upon the size and distribution of cracks on the tension side of reinforced concrete constructions.

Other cracking phenomena can be countered effectively by appropriate curing methods.

.

Curing of new concrete

New site-placed concrete is exposed to influences which may cause cracking and slow down its strength development:

▪ premature drying

▪ over-rapid cooling in the first few days

▪ excessively low temperatures or frost

▪ mechanical damage to the surface of the concrete

▪ hydration heat

▪ etc.

The simplest precaution is to leave the formwork on the concrete surface for longer. As well as the familiar extra curing measures, this measure should be carried out in any case.

.

Removing the load from the formwork from wide-spanned floor-slabs with support centres of over 7.5m

In the case of thin, wide-spanned concrete floor-slabs (e.g. in multistorey car parks), the following points must be remembered:

▪ When the formwork beneath these floor-slab spans is released (i.e. when the load is taken off the floor props), the floor props that are still in place are briefly subjected to additional loads. This may lead to overloading, and to the floor props being damaged.

▪ Please consult your Doka technician.

|

|

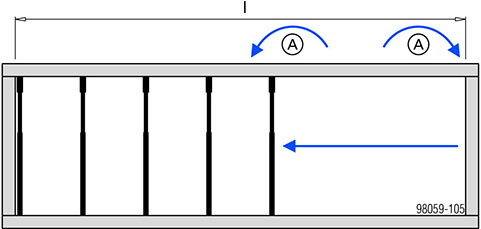

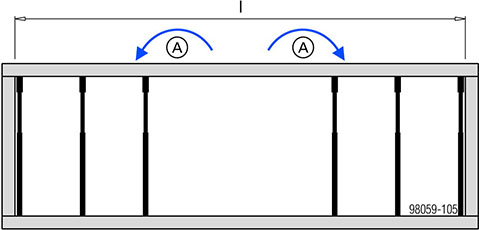

NOTICE As a basic rule: ▪ Stress-release should always be carried out working from one side towards the other, or from the middle of the floor slab (mid-span) towards the slab-edges. For wide spans, this procedure MUST be followed! ▪ Stress-release must NEVER be carried out from both sides towards the middle! |

l ... Effective floor-slab spans of 7.50 m and over

|

A Load redistribution |

.

Weighted maturity method

This procedure for determining the strength of the concrete with reference to its maturity has been technically established for several decades. By default, Concremote uses the maturity determination method developed by de Vree. Calculation of the De Vree weighted maturity is performed as follows:

|

|

Rg = 10 · |

[C(0.1T-1.245) - C(-2.245)] |

|

|

ln C |

|||

|

Rg ... weighted maturity per hour [C°h] |

|||

|

Concrete maturity is calculated by totalling the weighted maturities per hour. [1] |

|||

On the basis of the strength values from the calibration measurement, each maturity level has a particular compressive strength assigned to it.

This method for determining the concrete strength with reference to the maturity-level is addressed in the following technical documents and standards:

▪ DBV Code of Practice, 'Concrete formwork and stipulated stripping times', edition 06/2013

▪ DIN 1045-3, Concrete, reinforced and prestressed concrete structures - Part 3, edition 03/2012

with DIN EN 13670:2011-03

Note:

On customer request, Concremote can also be used with other methods of calculation (Arrhenius, Nurse-Saul, etc.). For more information, please consult your Doka contact person.

.

Use and benefits

Based on the measured strength data, the Concremote concrete monitoring system allows you to assure, optimise and speed up your building process by taking the appropriate measures.

Concremote can be used for the following:

▪ Determining stripping times in a reliable and precise manner – cycle time optimisation – cycle time reduction

▪ Process reliability – decisions are based on measured rather than estimated values

▪ Determining curing times by means of the measured strength development

▪ Safety in using climbing formwork

▪ Measurement of the hydration heat development in structural mass elements

▪ Seasonal adjustment and optimisation of the concrete mixture based on the continuous measurement of the compressive strength development (e.g. slow strength development in the winter period – change of the concrete mixture for faster strength development)

.