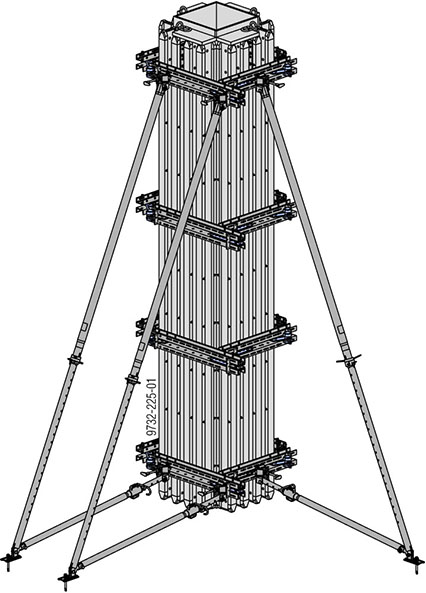

Design of column formwork

|

|

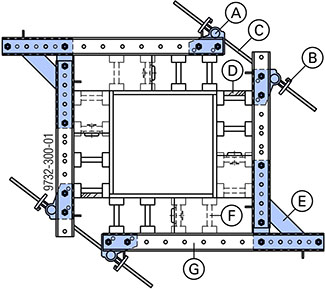

NOTICE ▪ To achieve exact plumbing & aligning of the column formwork, the best arrangement of the panel struts is as illustrated here. ▪ Always attach panel struts to free-standing formwork halves to prevent them from falling over. |

The Corner connecting plate 90/50 connects the walings rigidly and precisely across the corner.

Together with tie rods, the Universal angle tie bracket enables the walings to be diagonally tension-braced.

|

|

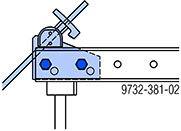

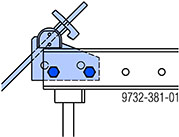

CAUTION Risk of tie overload if not correctly positioned! ➤ Make sure that the Universal angle tie bracket is bolted into the right holes for the Multi-purpose waling WS10 Top50 or WU12 Top50, depending on which type of waling is being used! |

|

Pinning holes for Multi-purpose waling WS10 Top50 |

Pinning holes for Multi-purpose waling WU12 Top50 |

|---|---|

|

|

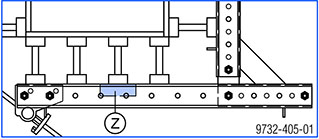

Note:

To prevent deformation of the waling profiles, put a site-provided wooden spacer (Z) between the profiles of each waling and nail it to the Doka beam.

|

A Universal angle tie bracket |

|

B Wing nut 15.0 |

|

C Tie rod 15.0 |

|

D Flange reinforcement |

|

E Corner connecting plate 90/50 |

|

F Doka beam H20 |

|

G Multi-purpose waling |

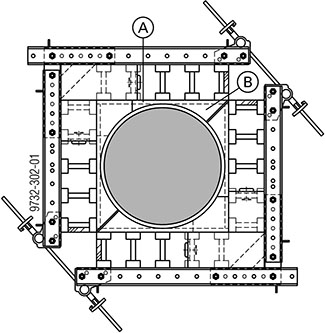

Circular column formwork

|

A Spacer plank |

|

B Profiled timber former |

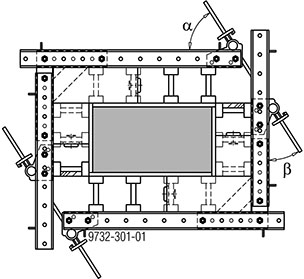

Rectangular column formwork

As far as possible, set the angles of the form ties in the same ratio as the length-to-width ratio of the column cross section.

α : β ≈ length : width

.