Carrying out the acceptance test

|

|

WARNING ➤ The load-bearing capacity of the anchoring point will depend upon how well the rock-anchor was fitted. ➤ The test-loading tests the load-bearing capacity of the anchoring point. ➤ If the material into which the rock-anchor has been fitted does not have sufficient bearing capacity, the tensioning instrument may suddenly loosen during the suitability test and/or acceptance test. ➤ For this reason, it is forbidden to stand beneath or behind the testing equipment. ➤ Secure the tensioning instrument so that it cannot drop. |

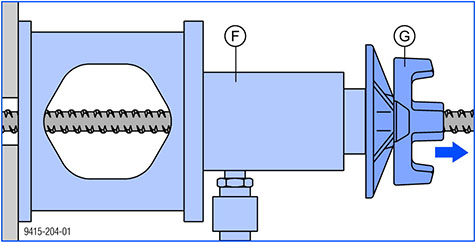

➤ For the acceptance test, push the "Hollow-piston cylinder with pressure support" (F) onto the tie-rod and mount the Super-plate 15.0 (G) .

➤ Apply the test force by operating the hand pump.

.

Trial test to determine the permissible load, based on DIN 4125

Suitability test

➤ On every building site, test at least 3 anchors at a location where unfavourable results may be expected.

➤ Load these test anchor-points until they fail, but not to more than max. 135 kN.

➤ The permitted anchor force is determined from the load at failure with a safety factor of 1.5.

|

Permitted capacity of the tie-rod to DIN 18216: 90 kN Specimen calculation: ▪ Load at failure: 80 kN ▪ Permitted anchor force: 80 kN/1.5 = 53.3 kN |

➤ With reference to the permitted anchor force, space out the anchors and determine the anchor force actually encountered (e.g. 50 kN).

Acceptance test

➤ Every anchoring point must undergo acceptance testing.

➤ The test load is 1.25 times the anchor force actually encountered.

|

Specimen calculation: ▪ Test load: 50 kN x 1.25 = 62.5 kN |

.