Securing the formwork against tip-over

|

|

WARNING ➤ Before anybody steps onto the surface of the formwork, its stability must be ensured by e.g. wall clamps or lashing straps. ➤ Transfer of horizontal loads as defined by EN 12812 must be ensured by other measures (e.g. by transferring these loads into the structure or using tie-backs). ➤ All cantilevered panels must be secured against overturning. |

|

|

For more information on tie-backs with lashing straps, see the section headed 'Floor formwork around edges' in the 'Panel floor formwork Dokadek 30 with drop head' User Information booklet. |

|

|

NOTICE ▪ Secure every floor prop in the 1st row of props with a Removable folding tripod. - Shoring height < 3.00 m: Removable folding tripod - Shoring height ≥ 3.00 m: Removable folding tripod 1.20m ▪ While the formwork is being set up, make a braced unit on the 1st pair of panels (with removable folding tripods), every max. 7.50 m and on the last pair of panels (without removable folding tripods) – see 'Practical example 1 - Braced unit on 1st pair of panels' & 'Practical example 2 - Alternative braced unit'. - Alternatively, tie-backs can also be attached (see 'Practical example 3 - Alternative tie-back'). ▪ Important to remember when mounting the floor prop (incl. cross head): in the typical zone, secure – with tripods – the props that have only 1 panel resting on them. ▪ Tie back the typical zones at the corners. ▪ Tie back cantilevering panels: - by the Scaffold tube 0.50m on every panel joint (see 'Practical example 4 - With bracing frame Eurex') - additionally, on the outside panels, by the middle bulkhead plate (see 'Practical example 5 - Tie-back at panel joint') |

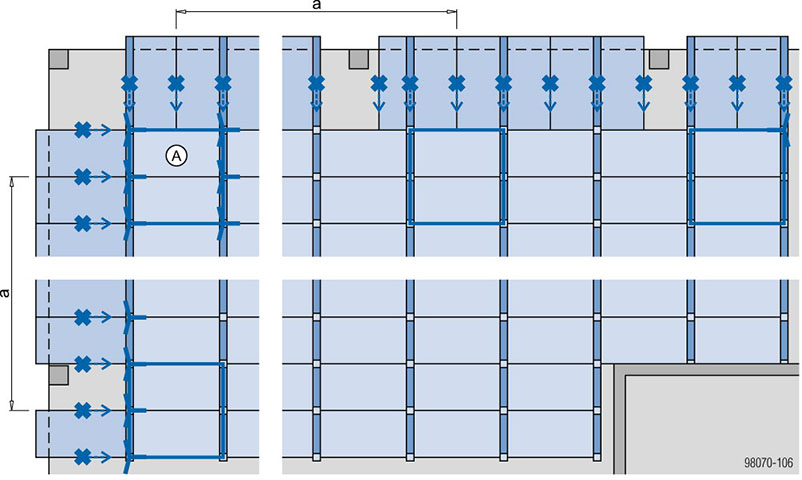

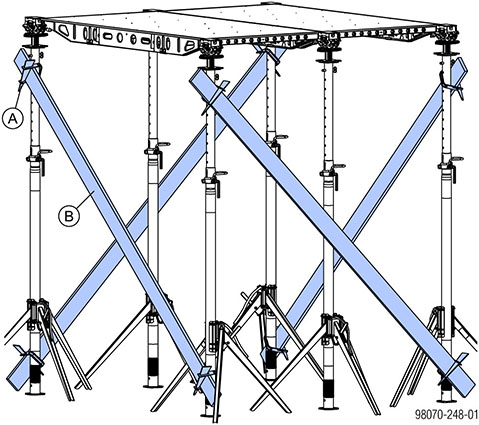

Variant with braced unit

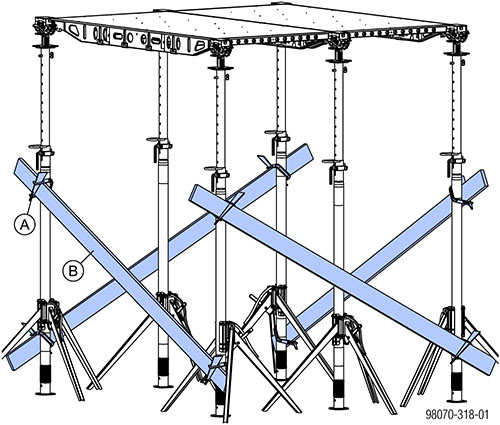

Variant without braced unit

a ... braced unit / tie-back on 1st pair of panels, every max. 7.50 m and on the final pair of panels

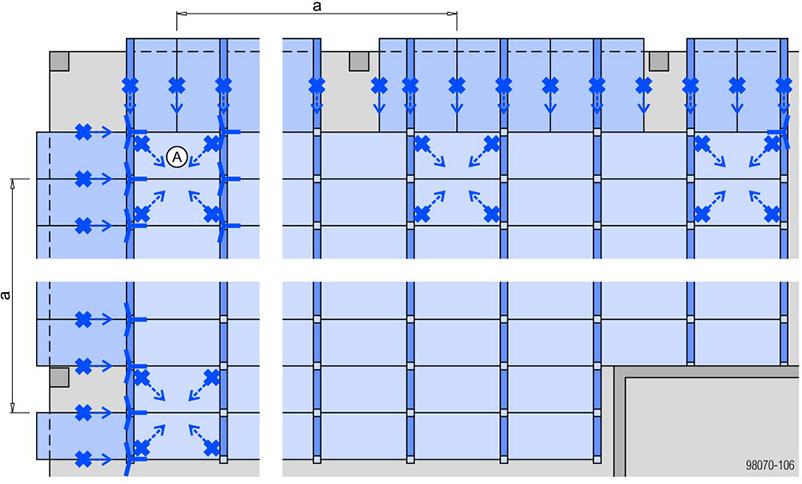

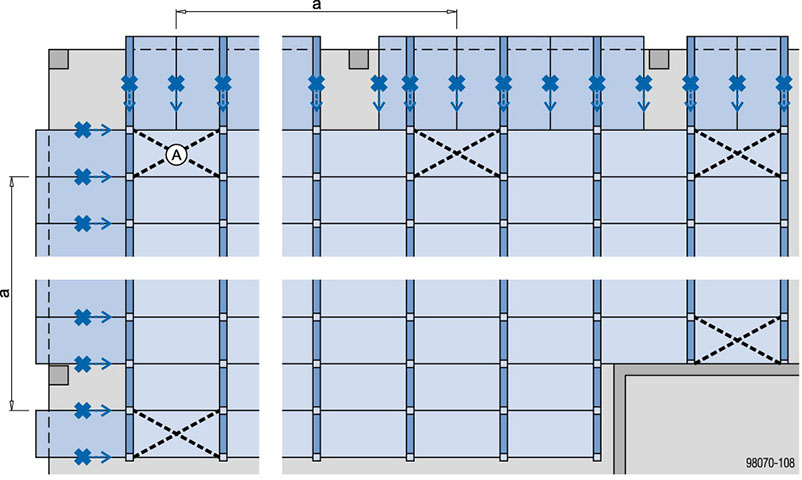

Variant with Bracing frame Eurex

a ... every 7.50 m and on last panel

|

A Starting unit |

Legend

|

|

Removable folding tripod |

|

Fixing point (e.g. with tie-back) |

|

Braced unit |

|

Bracing frames Eurex with diagonal crosses |

.

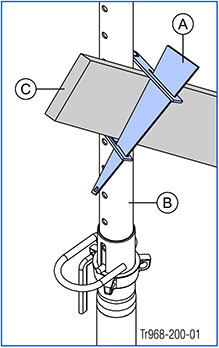

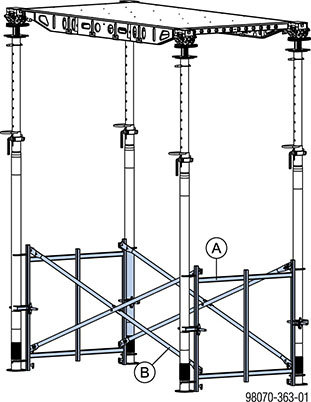

Bracing clamp B

Planks can be attached to the floor props as diagonal braces, using the Bracing clamp B.

|

|

NOTICE ▪ Only allowed to be used as a set-up aid. ▪ Not suitable for sustaining horizontal loads during pouring. ▪ Always hammer in the wedge from top to bottom! |

|

A Bracing clamp B |

|

B Doka floor prop Eurex 30 |

|

C Plank |

Possible plank/floor-prop combinations with the Bracing clamp B

|

Eurex 30 top |

Plank |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

2.4 x 15 |

3 x 15 |

4 x 15 |

5 x 10 |

5 x 12 |

5 x 15 |

|||||||

|

IT |

OT |

IT |

OT |

IT |

OT |

IT |

OT |

IT |

OT |

IT |

OT |

|

|

250 |

— |

✓ |

— |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

300 |

— |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

350 |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

400 |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

450 |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

— |

✓ |

— |

✓ |

— |

|

550 |

✓ |

✓ |

✓ |

✓ |

✓ |

— |

✓ |

— |

✓ |

— |

— |

— |

|

Legend: |

|

|

IT |

Inner tube |

|

OT |

Outer tube |

|

✓ |

Possible to combine |

|

— |

Not possible to combine |

.

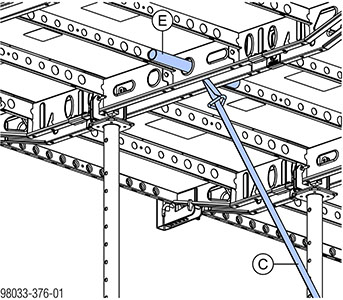

Practical example 1 - Braced unit on 1st pair of panels

.

Practical example 2 - Alternative braced unit

.

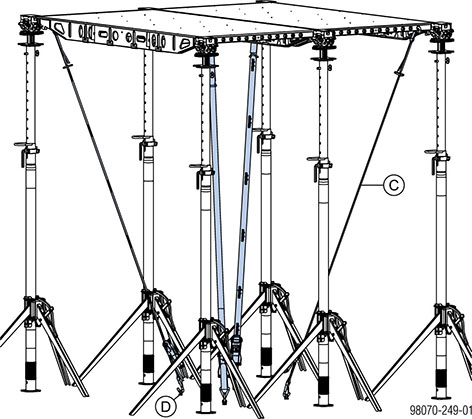

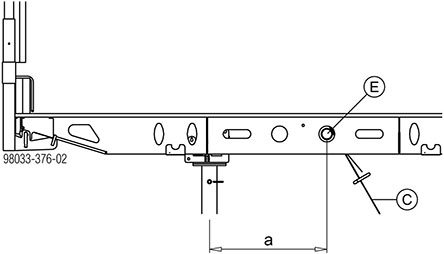

Practical example 3 - Alternative tie-back

.

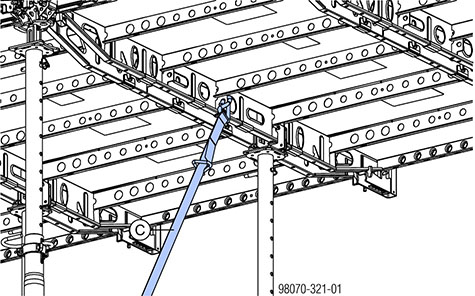

Practical example 4 - With bracing frame Eurex

|

A Bracing frame Eurex |

|

B Diagonal cross |

.

Practical example 5 - Tie-back at panel joint

a ... 50 cm

|

Permitted bracing force in longitudinal direction on the Scaffold tube 48.3mm 0.50m: 5 kN |

.

Practical example 6 - Tie-back in middle bulkhead plate

|

A Bracing clamp B |

|

B Plank |

|

C Lashing strap 5.00m |

|

D Doka express anchor 16x125mm |

|

E Scaffold tube 48.3mm 0.50m |

|

Permitted bracing force in longitudinal and transverse directions at the middle bulkhead plate: 5 kN |

.

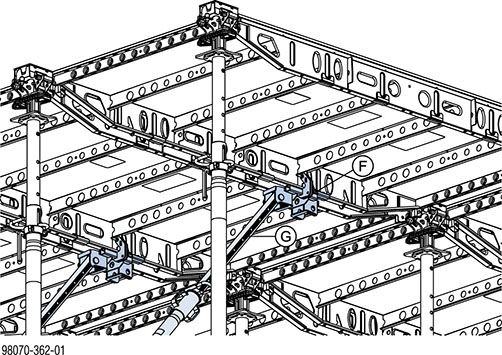

Practical example 7 - Tie back at the inter-panel joint at the one-third point with Dokadek plumbing strut connector

|

A Bracing clamp B |

|

B Plank |

|

C Lashing strap 5.00m |

|

D Doka express anchor 16x125mm |

|

E Scaffold tube 48.3mm 0.50m |

|

F Dokadek plumbing-strut connector |

|

G Plumbing strut 340 IB or 540 IB |

|

Permitted compressive force: 13.5 kN Permitted tensile force: 5 kN |

|

|

For details on use of the Dokadek plumbing strut connector see the section headed 'Sloping slabs' in the 'Panel floor formwork Dokadek 30' User Information booklet. |

.