Wall formwork

Instructions for assembly and use (Method statement)

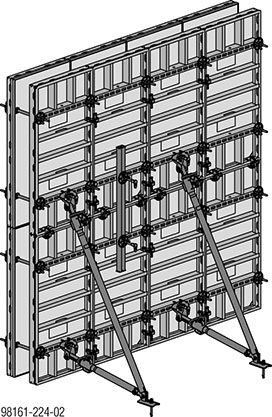

DokaXlight as a hand-set formwork

The sequence shown here is based on a straight wall. However, you should always start to form from the corner outwards.

.

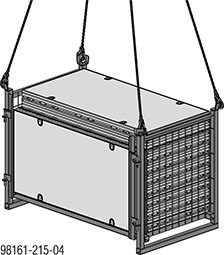

Transporting / handling the panels

➤ Unload panel stacks and multi-trip boxes and pallets from the truck (see the section headed 'Transporting, stacking and storing').

.

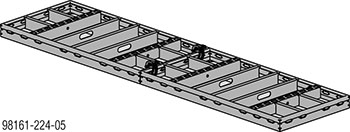

Closing the formwork

➤ Pre-assemble gang-forms 'flat on their backs' on an assembly bench (see 'Inter-panel connections').

➤ Spray the formwork sheet with release agent (see the section headed 'Cleaning and care of your equipment').

|

|

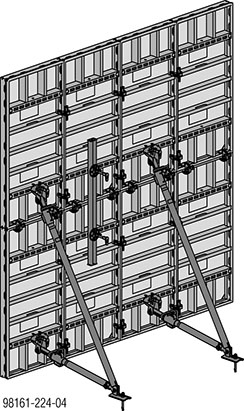

WARNING ➤ DokaXlight panels must be securely braced in every phase of the construction work! |

➤ Fix panels to the ground with plumbing struts or panel struts (see the section headed 'Plumbing accessories').

This stabilises the panels so that they cannot fall over.

|

|

NOTICE Never use a sledge-hammer to plumb and align the panels! This would damage the profiles of the gangs. ➤ Use only proper plumbing tools (e.g. a special pry-bar) that cannot cause any damage. |

➤ Continue lining up panels in this way, clamp them together (see the section headed 'Inter-panel connections') and fix them to the ground with plumbing struts or panel struts.

The panel assembly can now be exactly plumbed and aligned.

.

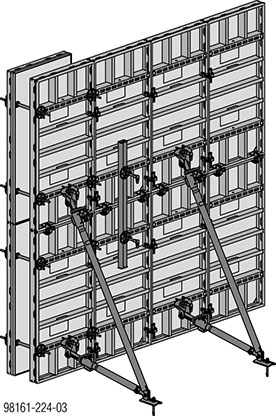

Erecting the opposing formwork:

Once the reinforcement has been placed, the formwork can be closed.

➤ Spray the formwork sheet of the opposing formwork with release agent.

➤ Set up the first panel of the opposing formwork.

➤ Fit the form ties (see the section headed 'Tie rod system').

Now the opposing formwork is also secured against tipping over.

➤ In the same way, carry on lining up panels, clamping them together and fitting form ties.

.

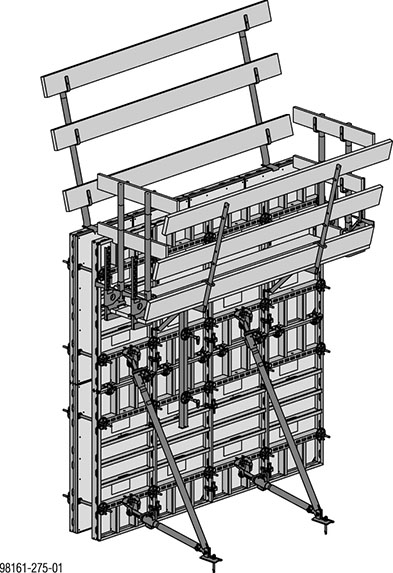

Mounting the pouring platform

➤ Install the pouring platforms and erect end-of-platform sideguards (see the section headed 'Pouring platforms with single brackets').

|

|

NOTICE Multi-panel gangs without an opposing formwork and with pouring platforms and Plumbing struts 260 must be fixed on the ground so that they cannot be dislodged. |

.

Ladder systems and working scaffolds

Platform stairway 0.97m

▪ wheel-around, fold-down platform stairway made of light alloy

▪ working heights of up to 3.00 m

(max. standing height 0.97 m)

▪ Stair width: 1.20 m

|

Max. load-bearing capacity: 150 kg |

|

|

Follow all country-specific regulations! |

.

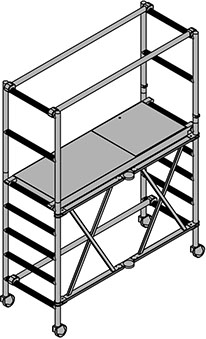

Wheel-around scaffold DF

▪ Collapsible wheelaround platform made of light alloy.

▪ variable working heights of up to 3.50 m

(max. platform height 1.50 m)

▪ width of scaffold: 0.75 m

|

|

Follow the directions in the User Information booklet! |

.

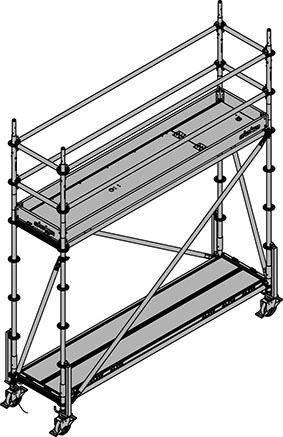

Working scaffold Modul

▪ Movable working scaffold

▪ variable working heights of up to 3.50 m

▪ width of scaffold: 0.73 m

▪ length of scaffold: 2.07 m

Ballast weight required

|

Standing height |

Ballast weight |

|---|---|

|

1.41 m |

40 kg |

|

1.91 m |

100 kg |

|

|

Follow the directions in the User Information booklet! |

.

Pouring

|

Permitted pressure of the fresh concrete: See the section headed 'Permissible fresh-concrete pressure'. |

Observe the following guidelines:

▪ The section headed 'Pressure of fresh concrete on vertical formwork – DIN 18218' in the Calculation Guide 'Doka formwork engineering'

▪ DIN 4235 Part 2 - 'Compacting of concrete by vibrating'

|

|

NOTICE ➤ Do not exceed the maximum permissible rate of placing. |

➤ Pour the concrete.

➤ Make only moderate use of vibrators, carefully co-ordinating the times and locations of vibrator use.

.

Stripping the formwork

|

|

NOTICE ➤ Comply with the stipulated stripping times. |

➤ Beginning with the opposing formwork, dismount the panels one by one - take out the pouring platform, remove the ties and remove the connectors to the neighbouring panel.

➤ Lift the panel away and clean concrete residue off the formwork sheet (see the section headed 'Cleaning and care of your equipment').

.