Load-bearing tower Staxo 100

The high-capacity high-speed shoring system

- safe up/down access is assured by ladders with slip-resistant rungs integrated into the frames

- individual safety aided by defined anchorage points for Personal protective equipment

- safe erection and dismantling ensured by "mounted-ahead" railings

- safe work stations provided by scaffold planking with and without manholes

- safe shoring of even very high loads, thanks to the load-bearing capacity of up to 100 kN per leg

- high stability, due to its 1.52 m wide frames

- excellent adaptability to different layouts, made possible by variable inter-frame spacing of between 0.60 m and 3.00 m

- continuous height adaptation with last-millimetre fine adjustment

- perfect adaptability, even to irregular layouts, by using a single leg

References

System

Staxo 100 frames

- extremely robust steel frames available in 0.90 m, 1.20 m, and 1.80 m height for simple height adaptation

- built-in connectors make the system easy to set up

- safety catches for fast and safe diagonal cross assembly

- integral ladders with non-skid rungs

- defined attachment points for Personal protective equipment

- easily connected to frame tubing couplings

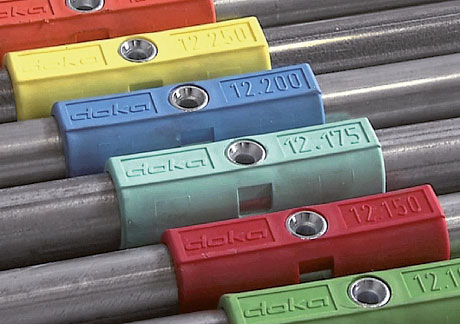

Diagonal crosses

- the firmly connected diagonal braces make the system quick and simple to erect

- different lengths of diagonal cross permit flexible inter-frame spacing, for cost-optimising the load capacity

- unmistakable length identification provided by colour-coded clips and embossed markings

Screw-jack heads and feet

- height adjustment possible right down to the last millimetre

- easy to operate, thanks to special thread geometry and integral fixing handle

- can be released with minimal physical effort, even when under load

Heavy duty screw jack

The screw-jack extension length of up to 2 m per load-bearing tower permits optimum adaptation to changes in the level of the support base, to downstand beams and to sloping slabs.

Very high workplace safety

- 'mounted-ahead' railings for erecting and dismantling the towerframes safely when this is done with the tower in the upright

- toeboard for safe workplaces e.g. beneath the towerframe superstructure

- a mounting-gallows makes it easy to pull up the towerframes

Added single legs

- for easy adaptation to unusual layouts

- continuous positioning possible up to 1.50 m away from the tower

- optimised equipment utilisation

Scaffold planking units

- for safety while assembling and working inside the scaffold

- lightweight aluminium or timber decking (width: 60 cm) with manhole and sturdy steel decking (width: 30 cm)

- at least two decking units (60 cm) needed on each storey of load-bearing tower

- integrated anti-liftout guard allows scaffold planking units to be added even when the load-bearing towers are pre-assembled in the horizontal

Utilisation

Simple and fast vertical stacking

- with few individual parts for simple use

- as connection sleeves and connecting pins are integrated in the frames

- thanks to logical set-up sequence

- because diagonal crosses are all clearly and unmistakably identified with colour-coded clips

Continuous height adjustment

- using the easy-to-operate screw-jack heads and feet for last-millimetre adjustment even when under load

- with a 2 m jack extension length per tower when the extra-strong Staxo 100 heavy duty screw jack is used

Stair tower

By combining standard Staxo 100 frames and pre-assembled aluminium stairway elements, this provides safe access to high-up workplaces.

Assembly using forklift truck or telescoping stacker truck

with this safe and effort-saving method, load-bearing towers are safely erected and dismantled in the upright as well as repositioned

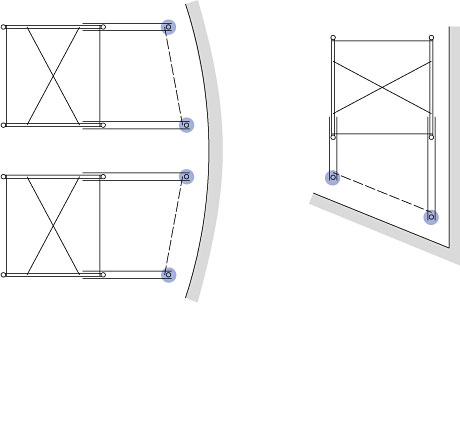

Adaptation to unusual layouts

by combining the towers with single legs

Erecting towers in the upright

with 'mounted-ahead' railings and scaffold planking units with manholes, for high safety

Fast, safe repositioning

using winches, Shifting carriages TG or forklift trucks

Erecting towers in the horizontal

a safe, fast method of erecting the towers

Suitable products

Stair tower 250

Doka Safety Systems

The sturdy, stable stair tower can be put together very quickly from frames and pre-assembled stairw…

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.