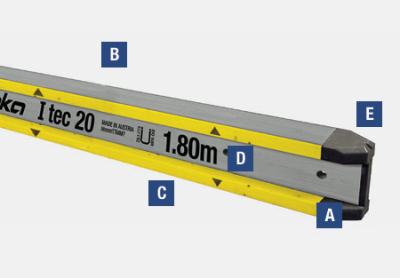

Composite formwork beam I tec 20

The high-performance beam that saves on quantities

![Composite formwork beam I tec 20]()

![Composite formwork beam I tec 20]()

Technical specifications:

Moment (M): 9 kNm

Shear force (Q): 20 kN

Rigidity (E x I): 640 kNm²

Weight: 5.6 kg/lfm

Certificate: Z-9.1-773High load capacity

achieved by innovative composite technology

- permitted bending moment M = 9.0 kNm

- permitted shear force Q = 20.0 kN

- rigidity E x I = 640 kNm²

- weight = 5.6 kg/lin.m

Save on equipment

thanks to optimised load capacity

- up to one-third fewer floor props on timber-beam floor formwork Dokaflex 30 tec

- up to 30 percent fewer form-tie points in wall areas Timberbeam formwork FF100 tec and Top 100 tec

- 50 percent fewer primary beams in the superstructures of fully loaded Load-bearing tower Staxo 40

More repeat uses

thanks to all-round protection

- extra-long lifespan, thanks to the proven 'top' beam-end reinforcement

- reduced close-out costs, thanks to the I tec sheet that protects the whole length of the flanges

(A) Top-beam-end reinforcement

(B) I tec sheet

(C) Beams marked in 50-cm increment-grid

(D) System holes

(E) Notch for chalk lineTimber formwork beam H20 top

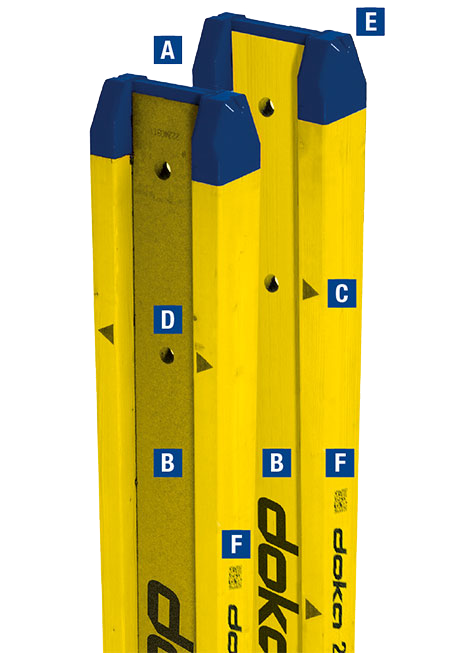

Up to triple the lifespan, thanks to built-in shock absorber at the beam end

![Timber formwork beam H20 top]()

- Reduced damage at the end of the beam

- Effective protection against moisture and UV radiation

since ends are sealed around web. - Fast, safe formwork set-up

with markings on the beam chords

(A) Top-beam-end reinforcement

(B) Web in version P

(C) Beams marked in 50-cm increment-grid

(D) 2 system holes at each beam end

(E) Notch for chalk line

(F) Labeling belt width side; Optional: Customising possibleTechnical specifications:

Moment (M): 5 kNm

Shear force (Q): 11 kN

Rigidity (E x J): 450 kNm²

Weight: 5.3 kg/lfm (P)

Certificate: EN 13377Timber formwork beam H20 eco

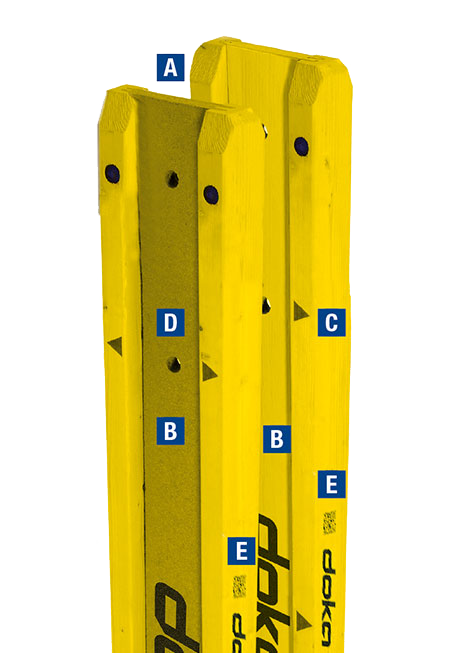

The tried-and-tested formwork beam with a solid-web design

![Timber formwork beam H20 eco]()

- High-quality beam chords

thanks to mechanical stress-grading - Less damage to beam-ends

owing to bevelled flange-ends and beam rivets - Easy to handle

because of its very low weight

(A) End-reinforcement with bevelled beam-ends and extra plastic rivet

(B) Web in versions N or P

(C) Beams marked in 50-cm increment-grid

(D) 2 system holes at each beam end

(E) Labelling belt width side; Optional: Customising possibleTechnical specifications:

Moment (M): 5 kNm

Shear force (Q): 11 kN

Rigidity (E x J): 450 kNm²

Weight: 4.4 kg/lfm (N) | 5.3 kg/lfm (P)

Certificate: EN 13377Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.