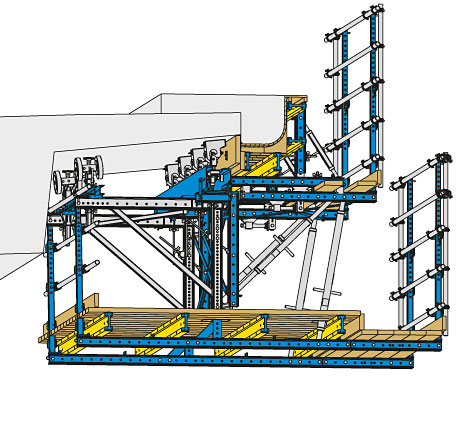

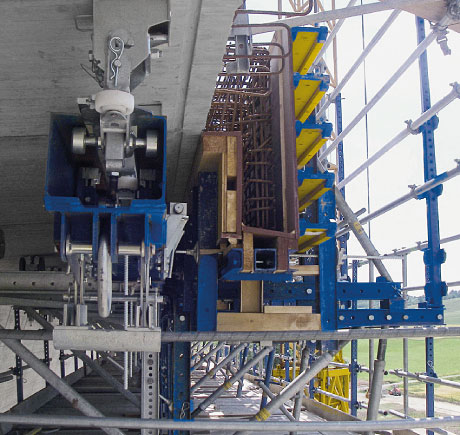

Forming wagon TU

The underslung bridge edge beam formwork for fast forming of cantilevered parapets

Streamlined forming operations aided by

- rentable all-in-one system with pre-assembled working platforms and parallel girderframe units / forming elements

- easy rebar and concrete placement operations from above

- underslung constructional design

- minimal disruption to traffic (e.g. during bridge rehabilitation) or to other construction operations when casting cantilevered parapets

Higher efficiency and swift construction progress, as

- the pre-assembled system units are very quick and easy to set up

- the horizontal and vertical formwork are removed simultaneously, with a swivel/tilt motion

- spindle struts are used for easy and accurate formwork set-up

Site crew are given maximum protection, by

- high standards of both active and passive safety

- pre-mounted working platforms ready for immediate use

- all-round scaffolding tubes for rugged side protection

- a built-in gravity brake which prevents any unwanted travelling of the forming wagon

![]()

Pre-assembled reinforcing cages can simply be hoisted into place from above.

References

System

Main areas of use

- medium to long bridge superstructures

- medium to high numbers of re-use cycles

- 'section-at-a-time' travelling

- rehabilitation of existing bridge superstructures

- cantilevered parapets with wide sidewalk spaces

- curve radii of 250 m and above

High standard of safety

- all-round, three-part side railings

- completely gapless platform decking

- separate working and erection platforms

- built-in gravity brake secures the forming wagon against accidental travelling

Flexibly adjustable

Thanks to the modular design concept of the load-bearing construction, and to the use of formwork elements assembled from Top 50 system components, just about any cross-section of cantilevered parapet can be accommodated.

Gravity brake

- automatically activated by gravity

Easy to operate

- high flexibility in terms of possible formwork configurations

- high degree of pre-assembly

- any type of suspension point can be used

Application Videos