Load-bearing tower d3

The high-performing and especially cost-effective shoring system for a wide range of applications

- thanks to lightweight components

- easy to assemble with fewer separate components

- rapidly set up by assembling in either the horizontal or the upright

- no tools needed for assembly

- simplified repositioning process thanks to variety of options

easily adapted to wide range of shoring tasks because

- the inter-frame spacing can be adapted to the load capacity

- precisely adapted to any length, width and height

- easily combined with all Doka Floor Systems

- high load capacity up to 94 kN per leg, due to the increased material strength of the d3 frame

- great flexibility makes for adaptability to project-specific requirements

- high-level stability with its 1.52 m wide frame

- hot-dip galvanized steel parts ensure a long lifespan

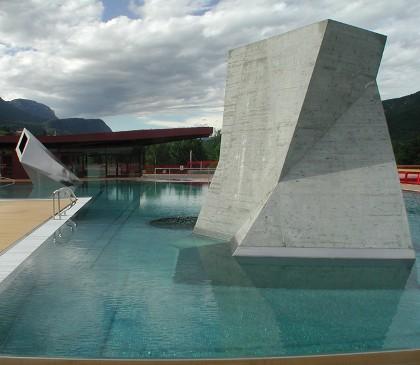

References

System

d3 frame

- hot-dip galvanized steel frames available in 0.90 m, 1.20 m, and 1.80 m height for simple height adaptation

- the built-in stop-ring of the d3 coupler prevents slippage into frame

- safety catches for fast and safe diagonal cross assembly

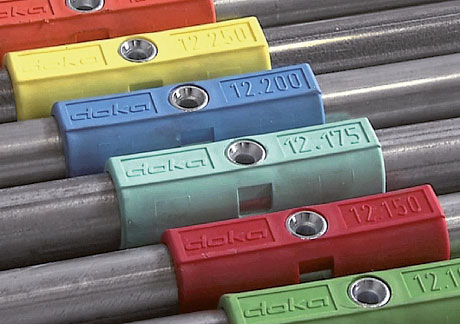

Diagonal crosses

- simple and fast assembly with permanently connected diagonal braces

- different lengths permit flexible inter-frame spacing for cost-optimising the load capacity

- clear identification of lengths through coloured clips and imprint

- available for inter-frame spacing of 60 cm, 100 cm, 150 cm, 175 cm, 200 cm, 250 cm and 300 cm for any frame height

Screw jack head and foot

- height adjustment exact to the millimetre

- practice-oriented spindle nut with option for connecting anti-liftout guard

- released with minimal physical effort, even when under load

- different screw-jack heads and feet for different options for use

Heavy-duty screw jack

- flexibly adapted to different heights

- screw-jack extension length up to 2 m per load-bearing tower permits optimum adaptation to changes in the level of the support base, to downstand beams and to sloping floors

Utilisation

Fast and safe assembly

- logical and easy assembly sequence

- assembly on the flat for maximum speed and safety

- simple and fast assembly and repositioning by crane

- the built-in stop-ring of the d3 coupler prevents slippage into frame and permits quickly setting up in the upright

Simple and fast repositioning

- no dismantling required for repositioning

- repositioned by crane, forklift truck etc.

- manual repositioning with attachable wheelsets

Areas of use

The Load-bearing tower d3 is ideal:

- as falsework for bridge-building and tunnelling, where high loads are generated and high structural integrity is essential

- in industrial and power-station construction, as a load-bearing tower for any application

- as well as in building construction, e.g. for multi-storey car-park decks, schools, hospitals and shopping centres and where large-area tableform units reduce forming times

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.