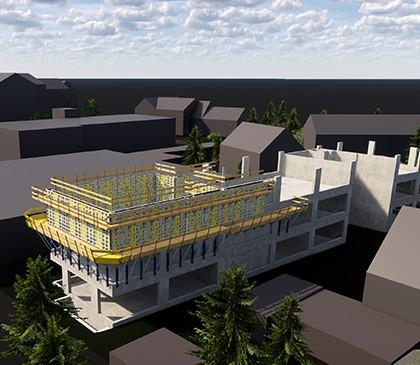

Dokaflex

The fast, versatile hand-set system

- downstand beams and floor extensions can easily be solved 'within the system'

- perfect adaptability to columns and walls

- optimising for different slab thickness

- suitable for shoring filigree slabs

- selection from two beam lengths makes for simplified logistics and less time spent searching

- fast and easy forming of floors up to 30 cm thick made easy with beam markings

- reduced equipment need thanks to statically optimised beam and prop spacing with Dokaflex 20

- high numbers of re-use cycles and reduced close-out costs, due to the shock absorbers and protectors on the system components

- site logistics are simplified by the perfectly co-ordinated system components

- first-rate concrete surfaces, as any type of form-facing can be selected

References

System

Beam H20 top

Up to 3 times the lifespan, thanks to built-in shock absorber

- effective protection against moisture and UV radiation, as beam-ends are sealed around web

- fast, safe formwork set-up by referring to markings on the flanges

- unmistakably identifiable, thanks to labelling option

Formwork sheet 3-SO

- first-rate concrete results through choice timber and superior surface treatment

- minimal deformation and reduced cleaning costs through continuous edge strip

- long lifespan thanks to specially aligned face-ply and high dimensional stability

- low cost due to high reuse numbers

- clearly recognizable thanks to labelling option

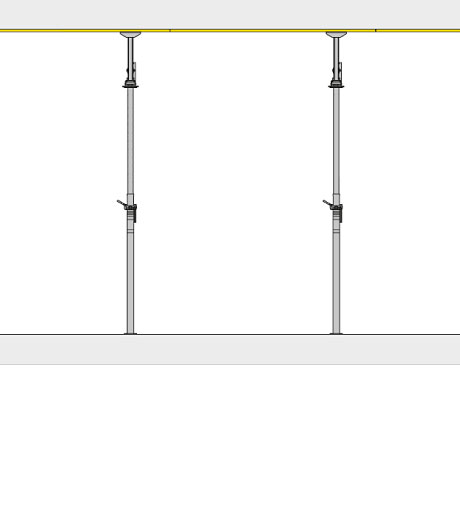

Floor prop Eurex top

Floor prop with impact protector

- durable, due to impact protector

- easy-to-turn adjusting nut, thanks to special thread geometry

- less physical effort needed because the prop is lightweight

- operational safety achieved by consistently high load capacity of at least 20 and/or 30 kN in accordance with EN 1065 – Class D/E

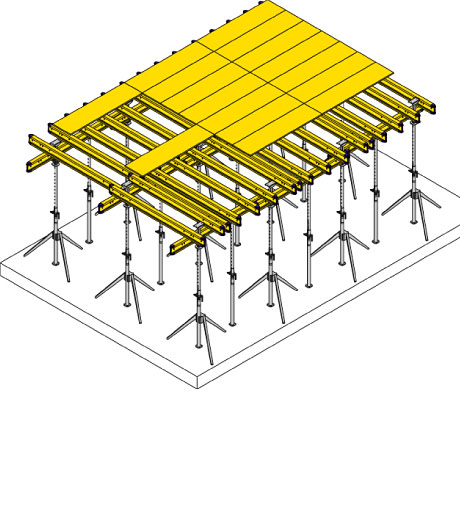

Utilisation

Dokaflex 1-2-4 with built-in 'set-up logic'

Here's how easily the system works

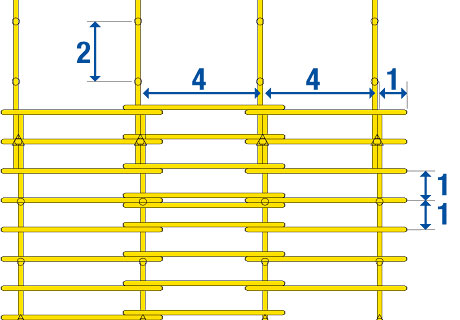

1-2-4 – these are the maximum spacings for setting-up Dokaflex 1-2-4. Triangular marks on the beams serve as a built-in 'measuring tape'

- 1 mark = maximum spacing of secondary beams

- 2 marks = maximum spacing of props

- 4 marks = maximum spacing of primary beams

- marks on the beams show you maximum spacings between secondary beams, props and primary beams, for floors up to 30 cm thick

- having only two different beam lengths simplifies logistics and reduces the time spent searching

- you can tell at a glance whether the formwork has been set up correctly

Dokaflex 1-2-4 slide rule: equipment needs for large and small rooms are easily calculated based on the floor area available from your Doka adviser

Dokaflex 20 with optimised commissioning quantities

Individual project requirements

- Dokaflex can be adapted to the most complex layouts; it also optimises the formwork equipment needed

- beam and prop spacings are optimised depending on the layout, and in accordance with the floor load

- infill zones are formed quickly and easily without additional props by telescoping the formwork beams

For customised forming operations

- very little equipment is needed thanks to statically optimised beam and prop spacings, which are in accordance with the room geometry and the loads generated

- downstand beams and floor extensions can be solved easily 'within the system'

- much lower quantities commissioned

Technical slide rule Dokaflex 20: quick and easy optimisation of beam and prop spacing directly on-site available from your Doka adviser

just a few steps and your beam spacings are calculated directly on our website or by using our app: www.doka.com/apps

Quantities commissioned are reduced because approx. 75 percent of the system components become available for reuse, thus yielding optimal utilisation of the equipment. The stripping process is very efficient and cost-optimised because it is defined.

Dokaflex with Xtra head for early stripping

Early stripping

The Doka Xtra head permits early stripping, thereby speeding up the whole workflow.

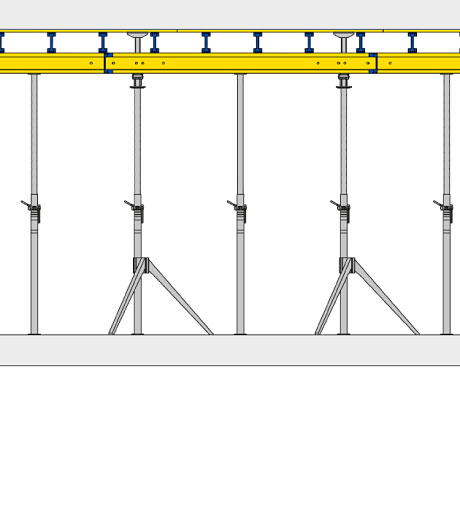

Initial situation

Floor slab with Doka Xtra formwork still in place

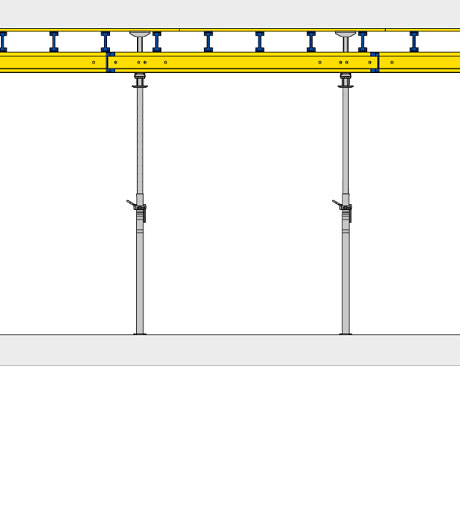

Step 1

Folding tripods and intermediate props are removed

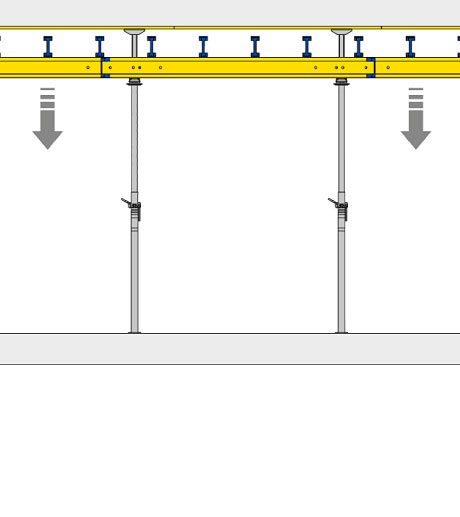

Step 2

Floor-slab formwork is lowered using the Doka Xtra head

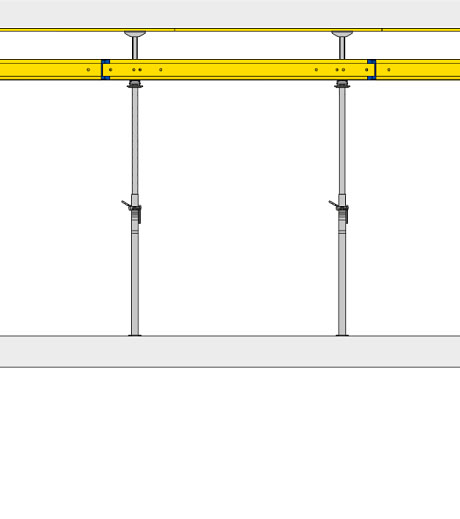

Step 3

The secondary beams, and most of the formwork sheets, are removed

Step 4

The primary beams are removed. The temporary reshoring stays in place until the concrete has attained sufficient load-bearing strength.

Doka Xtra head

If the project requires early stripping, the Dokaflex timber-beam formwork system can be equipped with the Doka Xtra head. It permits early stripping and most of the formwork equipment can be reused right away in the next casting section.

Suitable products

Sealings for fair-faced concrete

Doka System Components

Reliably casting concrete surfaces in the desired fair-faced concrete category is quite a challenge,…

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.