One of the most important road construction projects in Austria is currently advancing in high gear: construction of the S 10 Highway through the Mühlviertel district. Doka, with its high-performing products, is involved at numerous project locations along the construction site stretching the length of 22 km.

Press Contact

Impressions

ASFINAG, Autobahnen- und Schnellstraßen-Finanzierungs-Aktiengesellschaft, (an Austrian highway and carriageway financing corporation), invested around EUR 718 million in order to realise this gigantic infrastructure project. As part of European route E55, the S 10 Highway serves as an important strategic connection to the South Bohemian and Baltic Sea regions. Furthermore, the eagerly awaited commuter route is intended to significantly reduce traffic as well as increase road safety. As a result of local topography, construction of the S 10 requires enormous earth movements and numerous building operations in order to overcome natural obstacles. In order to level the path for the S 10 and its future users, the construction firms involved are building four tunnels, four subsurface tunnels, five interchanges, seven overpasses, 17 bridges, six passages, one gallery and several retaining walls.

This type of mega-project is not common and demands near-perfect planning, coordination and implementation know-how from all participants. Here, Doka functions as competent formwork partner for construction firms and supplies products and services for multi-faceted requirements. Execution and technology for infrastructure buildings are subject to particularly stringent challenges. Doka's sophisticated solutions result in efficient and safe construction of the many tunnels and bridges. To ensure rapid and smooth construction progress, Doka delivers formwork materials "just in time" - to the right place at the right time. Thus construction firms are able to focus on their core competency, namely construction. "In Doka we have a reliable partner whose product quality is as convincing as its implementation and quick response times", reports Porr Bau Ltd. site manager Franz Hrebik. One of the essential challenges was producing formwork for a wall area exceeding 13,000 m². In contrast to conventional standard procedures, Doka was able to save around 4,900 form ties thanks to its innovative formwork solution. As a result, working time and costs were significantly reduced and construction progress accelerated.

In the following, you will get insight into the "longest" construction site in Austria and some of its exciting projects:

This type of mega-project is not common and demands near-perfect planning, coordination and implementation know-how from all participants. Here, Doka functions as competent formwork partner for construction firms and supplies products and services for multi-faceted requirements. Execution and technology for infrastructure buildings are subject to particularly stringent challenges. Doka's sophisticated solutions result in efficient and safe construction of the many tunnels and bridges. To ensure rapid and smooth construction progress, Doka delivers formwork materials "just in time" - to the right place at the right time. Thus construction firms are able to focus on their core competency, namely construction. "In Doka we have a reliable partner whose product quality is as convincing as its implementation and quick response times", reports Porr Bau Ltd. site manager Franz Hrebik. One of the essential challenges was producing formwork for a wall area exceeding 13,000 m². In contrast to conventional standard procedures, Doka was able to save around 4,900 form ties thanks to its innovative formwork solution. As a result, working time and costs were significantly reduced and construction progress accelerated.

In the following, you will get insight into the "longest" construction site in Austria and some of its exciting projects:

Neumarkt Tunnel

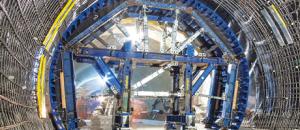

Each of the Neumarkt Tunnel tubes is 1,970 m long with an inside radius of 5.05 m. For its tunnel formwork, the construction company uses the modular heavy-duty supporting system SL-1 in combination with the large-area formwork Top 50 and high-capacity hydraulics. Given the limited space available, this formwork solution provides the necessary flexibility due to the variable arrangement of system beams, waling units and struts.Pernau Subsurface Tunnel

Both tubes of the Pernau Subsurface Tunnel are 270 m long and feature a round cross-section. The new tunnel system DokaCC is deployed successfully in this project. In close cooperation between construction firms, planners and Doka, the tunnel formwork system was conceived so that it can be adapted to the complex, slightly rotating geometry of the structure in the course of the procedure.Ganglsiedlung Subsurface Tunnel

The Ganglsiedlung Subsurface Tunnel consists of two tubes, each 275 m long. Their clear widths measure 9.80 m with a clear height of 5.68 m. This structure was formed with the tunnel system DokaCC as well. Here, the flexibility of the tunnel system for cut-and-cover construction is clearly evident. The same forming wagon is used at another time for a second project location with a different cross-section. Adaptation to both structure geometries requires little additional material cost.Walchshof Subsurface Tunnel

Doka's large-area formwork Top 50 is used for forming the 13,344 m² wall area of the Walchshof Subsurface Tunnel. Compared to the standard solution, using the quick-release nut designed to smoothly release anchoring tensile forces of up to 220 kN results in savings of 4,900 form ties, thereby significantly lowering cost and working time.Feldaisttal Bridge Freistadt Nord Foundations and Piers

The construction company used Doka's high-performing framed formwork Framax Xlife to build the foundations. The piers of the 260-m-long arched bridge measuring up to 60 m in height are built rapidly and safely using the climbing formwork MF240. Doka provides pre-assembled platforms and formwork panels for piers and pier heads; the construction company is able to focus completely on the construction process.This could also be of interest for you:

Do you have any questions on the article? Get in touch with us!