Site Docu

and Analytics

Digitise your construction site.

Easy. Fast. Convenient.

New customer login for the construction site software now available!

Site Docu and Analytics for connected and digital construction site management.

The central tool for digital and efficient construction site management from site planning to completion and analysis.

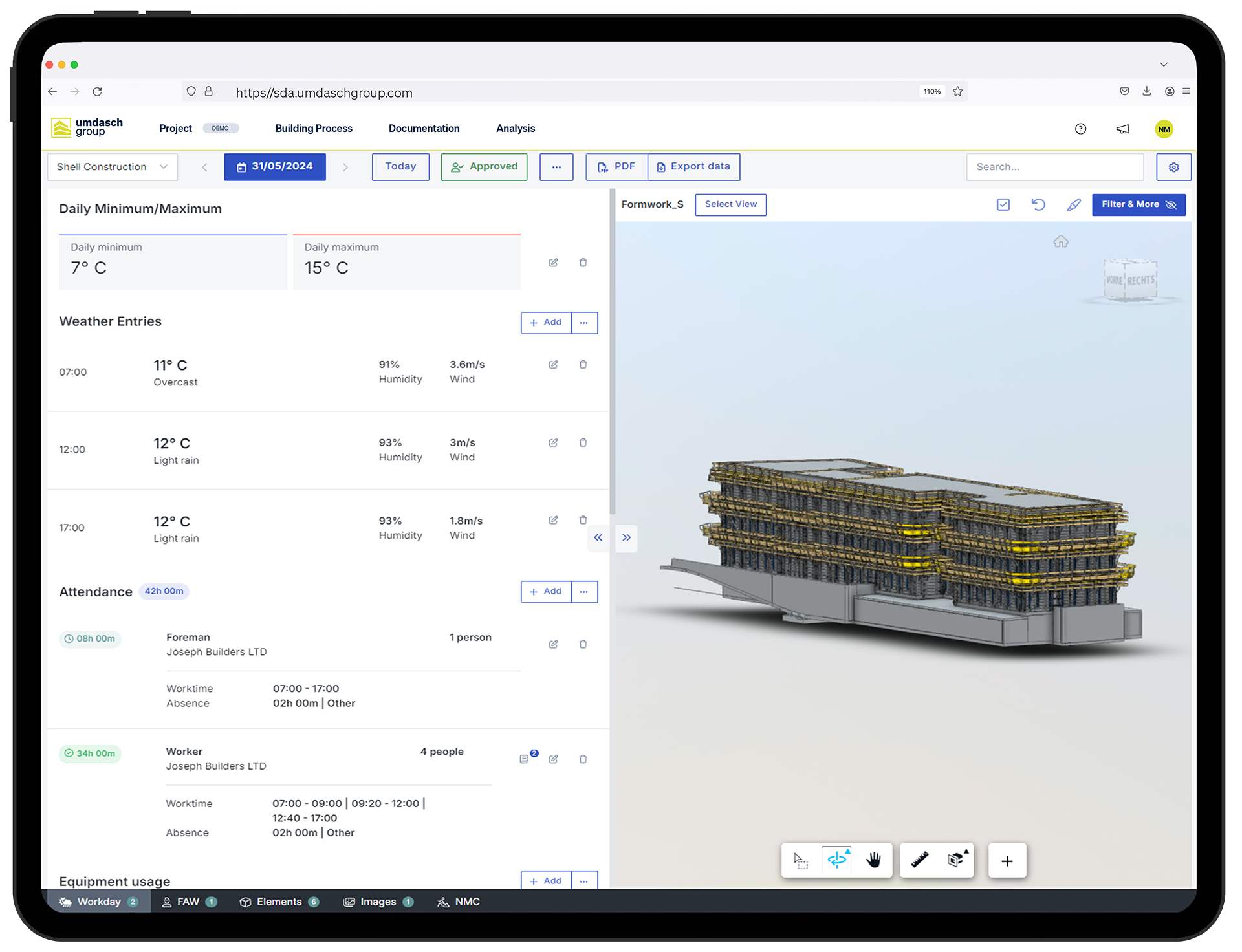

Digital construction diary

Save time with online daily construction & management reports

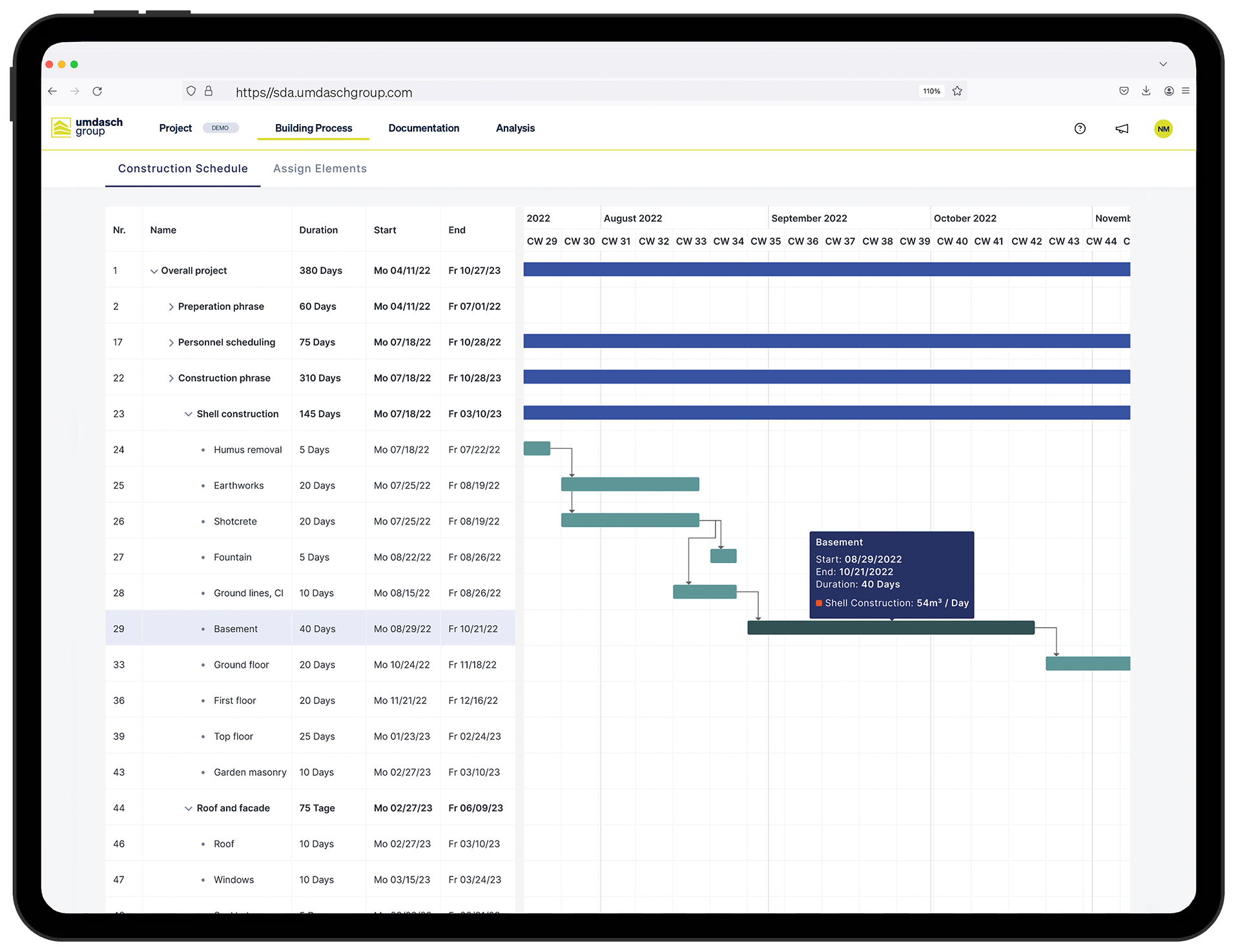

Construction site scheduling

Material forecast, BIM 4D and full overview at a glance

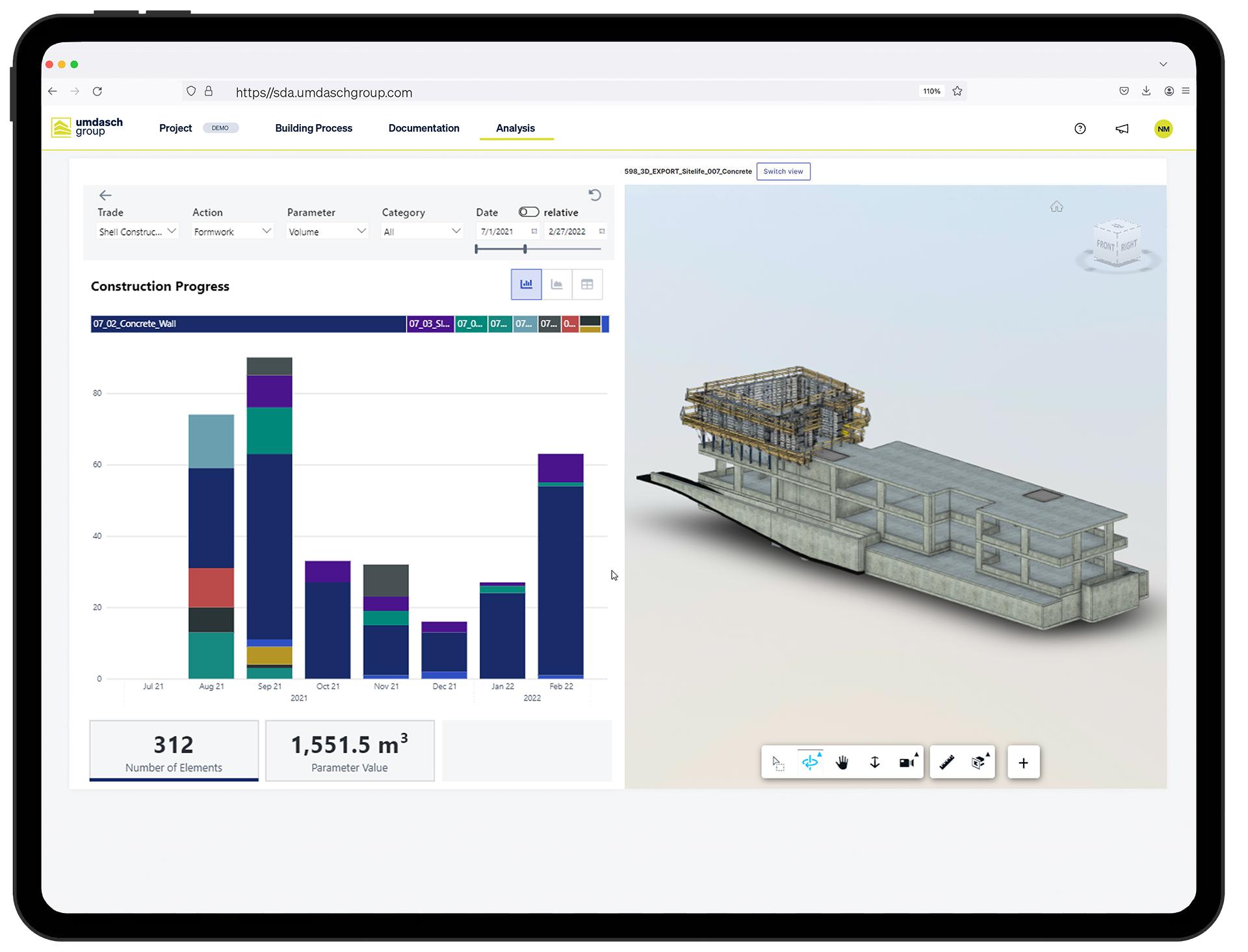

Project controlling

Improvement of the construction process through target/actual comparisons, material, hourly and equipment analyses

5D

Documentation of time of completion, man-hours and use of equipment

Site Docu and Analytics | 30-day free trial!

Your advantages

Time savings due to reduced documentation effort

Efficient collaboration thanks to a transparent, digital construction schedule

Cost savings thanks to precise resource planning

Optimization of construction processes

Simplifies data analysis and data export

Error prevention by linking 2D plans/3D model with construction schedule

Digital construction diary

With the digital construction diary, you can document the day's work easily, online and in a time-saving manner (2D / 3D BIM-based). Force account works or materials are documented simply and digitally using control reports.

Highlights:

- Linking the construction progress with the BIM model

- Structured data in one place (plans, PDFs, images, ...)

- Digital approval processes with integration of the site supervision/ÖBA

- Linking with the bill of quantities possible (ONLV, GAEB)

Construction scheduling

With construction scheduling, you have an overview of all dates and deadlines - online, accessible from anywhere and always customisable.

Highlights:

- Linking the construction schedule with the 3D model (BIM 4D)

- Automatic material and resource planning

- Import of existing construction schedule or simple creation in the software

- Linking of model elements with times from the schedule (model-based cycle planning)

Real-time project analysis

Analysis made easy with informative visualisations of construction site data. This allows you to immediately recognise potential for improvement and disruptions in the construction process.

Highlights:

- Efficient controlling through target/actual comparisons

- Material and personnel deployment at a glance

- Numerous filter methods on a time and model basis

- Performance determination through efficient construction progress analyses with just a few clicks (3D / BIM-based)

- Simple data export as a basis for invoicing

Customers who already work successfully with Site Docu and Analytics:

References:

Waizenauer Bauunternehmen GmbH & Co. KG

Our customer Waizenauer Bauunternehmen GmbH & Co KG relies on Site Docu and Analytics to provide the construction site team with a simple and intuitive tool for working and to be able to focus on the essentials in the stressful day-to-day construction work.

Lang Bau GmbH & Co. KG

Our customer Lang Bau GmbH & Co relies on Site Docu and Analytics in order to realise an economically successful construction project in times of ever more complex requirements for construction projects, increasing deadline and price pressure, delivery bottlenecks and staff shortages.

Free

Free of charge

✓ Unlimited users

✓ Online construction scheduling (limited functionality)✓ Digital documentation (limited functionality)

Basic 2D

99.00 EUR

month / project

✓ Usable with pdf plans

✓ Unlimited users

✓ Online construction scheduling✓ Digital documentation incl. construction diary & director's report✓ Construction data analysis with target/actual comparisons

Basic 3D

399.00 EUR

month / project

✓ Usable with 2D plans and 3D model

✓ Individual reports and analyses

✓ Unlimited users

✓ Online construction scheduling✓ Digital documentation incl. construction diary & director's report✓ Construction data analysis with target/actual comparisons

Enterprise

individualised

✓ Individual pricing for your group solution✓ Personal advice and training on the construction site

✓ Individual reports and analyses✓ Unlimited users✓ Online construction scheduling✓ Digital documentation incl. construction diary & director's report✓ Construction data analysis with target/actual comparisons

Your contact person

Are you an innovative construction company and interested in the construction site software Site Docu and Analytics? Get in touch with our experts!