Forming speed in a new dimension

Form walls even more cost-effectively

The Framax Xlife plus form tie can be operated from one side. It is the centrepiece of the Framax Xlife plus framed formwork system. It makes your job of erecting and stripping formwork for walls fast, cost-effective and safe. Due to its conical shape, there is no need for jacket tubes and cones. Innovative: Form-tie sleeves are completely sealed without wearing parts.

Your benefits with Framax Xlife plus

![Icon Speed]()

The sprinter

among form-ties

Lightning-fast assembly thanks to

new-generation form-ties- no second crew member needed

- no installation of jacket tubes and cones

- even easier and faster stripping

- no subsequent re-adjustment, because the setting is not changed when the formwork is stripped out

- up to 152 kN/anchor permissible tensile force with tie-rod system 20.0

Record-breaking speed

With effortless, damage-free tightening and releasing of the form ties using a ratchet or impact wrench

![FXP Vorteile Anker]()

No disassembly

as panels are stacked even faster as there is no need to remove integrated form-tie nuts

![FXP Vorteile Anker]()

No wearing parts

thanks to steel-on-steel seal for form ties in the form-tie sleeves

![FXP Vorteile Anker]()

Reliable setting

of wall thickness in 0.5 cm or 1 cm grid by grooves, not threads; the stop cylinder has a yellow end for a fast sight-check of 1 cm grid setting

![FXP Vorteile Anker]()

No search times

thanks to an integrated parked tie position

![FXP Vorteile Anker]()

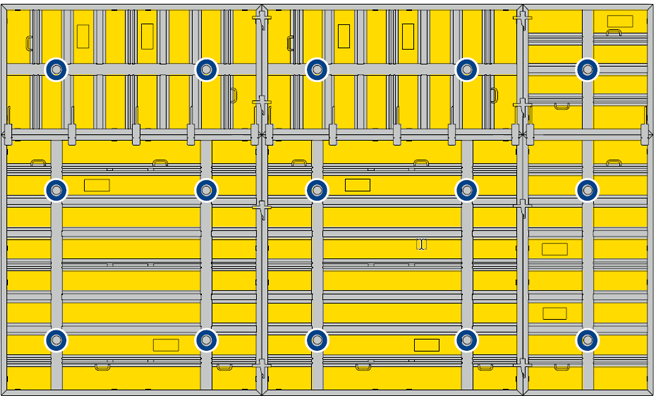

The system logic.

Easy. Perfectly co-ordinated panel formats.

The system logic of Framax Xlife plus optimises material utilisation and logistics for a better overview on site. The basic panel is square and standard panels top-fix or bottom-fix set longside horizontally or vertically; there are only a few standard-panel formats - no need for small panels of many different sizes to make up gangforms.

Framax Xlife plus can be combined with the proven Framax Xlife framed formwork panels.

Both formwork systems use the same accessories (connectors, universal walings, plumbing accessories, platforms).

by utilising the form-tie points

New accessories

For working even more efficiently on the formwork.

![tools icon]()

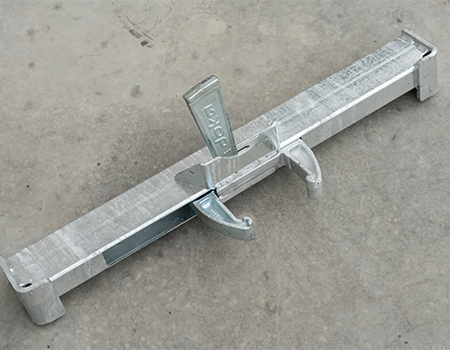

Framax positioning lever

- The new Framax positioning lever makes the job of positioning gang-forms fast, easy and gentle on the material.

Framax aligning clamp

- Vertical stacking up to 6.60 m with only one part - the Framax aligning clamp makes it possible.

Do you have questions about the system?

We will be happy to inform you. Get in touch with us!Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.