Understanding how to break through

Formwork solutions for your tunnel project

_Understanding complex tunnel projects

_Understanding such as this is based on our experience from infrastructure projects around the globe. We rely on our flexibility and innovation as the key to success.

Successful and economic implementation of tunnel structures requires flexibility. The people at Doka are your expert partner right from the start. We know how to listen and ask the right questions in order to identify challenges and the factors that influence a project. This is how together with our partners and their customers we get moving on time and in the right direction. The process often starts long before the actual project implementation gets under way.

Another Factor for success is our broad range of formwork solutions – from standard system through to individual formwork. We always try to find the solution best suited for our customers – regardless of tunnel construction method. What's more, our international logistics system allows us to respond quickly to unforeseeable influences, no matter where they occur.

This is why we are your high-performing and reliable partner in tunnel construction.

_Understanding requirements

Suitable solutions for any tunnel construction method

The aim of every formwork-engineering solution is to bring the construction project in on-budget. While complying with the highest quality and safety standards. The paths leading to this goal are many and varied. This is the reason Doka has designed its formwork systems for modular use and maximum interoperability. The result is an advantage in time and money that makes our customers so competitive.

Cut-and-cover construction

With cut-and-cover construction for tunnels, an excavation pit is dug which is then kept supplied from above grade. After completion of the tunnel shell, the excavation pit is filled in again and the tunnel sections are covered with excavated soil. Most cross-sections of cut-and-cover construction tunnels are shaped like a frame or rectangle and built using non-monolithic, partially monolithic or monolithic methods.

Your benefits with Doka

You will get innovative and cost-optimised formwork solutions that are based on rentable modular systems. Perfectly coordinated with the cut-and-cover construction and the project's challenges as well as designed to meet our customer's demands. We use our range of services to complement our economical products and develop the best-possible formwork solutions.

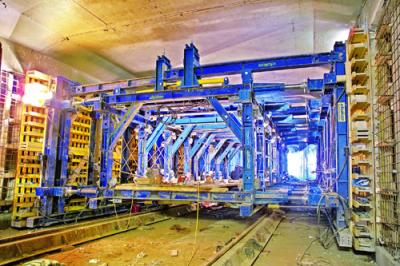

Mining-type (underground) tunnel construction

For tunnels built with the mining – i.e. bored underground – construction method, the required cavity is created by conventional or mechanical heading work and continuously stabilised. After ensuring the success of several safeguards in the process such as shotcrete and watertightness, the tunnel's inner shell is complete using various options.

Your benefits with Doka

Project-specific complete formwork solutions that can be rented for time- and cost-optimised construction progress on all cross-sectional dimensions, from galleries to tunnels and even caverns.

Top-cover method

For tunnels built using the top-cover method, also known as the 'top-down' method, the first step is a pre-excavation pit. Working from the base of this pre-excavation, bored cut-off walls or slurry walls are then constructed for lining the pit. The next step is to cast the tunnel roof (i.e. the top cover) onto these trench walls and the soil between them. Then the excavation pit is filled in and the tunnel cover slab covered with replaced soil. After that the tunnel is dug out beneath the top cover and single-sided walls as well as the inner shell's floor plate are poured one by one.

Your benefits with Doka

Just-in-time delivery of a project and customer-oriented formwork solution consisting mainly of standard formwork that can be rented and meets or even exceeds daily requirements. This process ensures that the surface of the structure is sealed as quickly as possible.

Project-specific planning and our additional services round out the benefits to our customers and the site.

Formwork solutions to fit your tunnel project's needs:

For ever-higher quality requirements and differing tunnel-building methods

Contact for large-scale projects

With its ability to deliver quality solutions for ever-greater demands placed by the different tunnel-building methods, Doka is a dependable partner for your tunnel project, offering global consulting and hands-on planning- and engineering capabilities: project implementation by specialists.