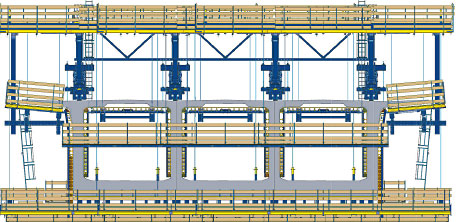

Cantilever forming traveller

Formwork and shoring from one single supplier

Reduced costs

from having a rentable and precisely co-ordinated all-in-one solution

- because the equipment is rentable, it does not need to be pre-financed

- the small number of separate parts keeps site-erection times short

- easy-to-understand, ergonomically engineered system makes for fast repositioning and cycle times

- its modular components help it adapt flexibly to different geometries

Smooth project progress

because of the detailed co-ordination between the CFT and the formwork

- the all-in-one, single-sourced package means there are fewer interfaces to the superstructure designer

- project-specific Operating Instructions describe all worksteps in detail

- short delivery times thanks to rapid availability of standard system components

- time-savings thanks to ongoing support from experienced Doka Formwork Instructors

Safety at all times

in every phase of the work

- fully railed-in working platforms on all levels

- the CFT's anchorages are hydraulically test-loaded before every pour

- slide bearings secure the CFT against unwanted travelling on longitudinal gradients

References

System

Optimised longitudinal trusses

- ergonomically designed, with upward-extended longitudinal trusses for more headroom

- horizontal pre-assembly, incl. of ladder system and catwalk, is possible

Universal anchoring cross-beam

- the suspension rods can be flexibly positioned for adaptability to different bridge geometries

- asymmetrical cross-beam configurations are possible where space is constricted due to e.g. neighbouring structures

- broad working platform from which the suspension rods can be operated safely

- pre-assembly is possible, incl. of platform

Modular design concept

The longitudinal trusses can be variably positioned, which makes it easy to adapt the cantilever forming traveller to variable-width or multi-cell cross-sections.

Pre-assembled platform system

- on all work-deck levels

- with integrated ladderways complete with ladder cages and self-locking manholes

- generously sized workplace access routes for safe, efficient working

Innovative drive unit

- permanent self-locking safety feature using slide bearings to guard against unwanted travelling, effective up to a longitudinal gradient of six percent

- incorrect operation of this safety feature is impossible, as it is always active

Bracing located on outside

- makes it easier and quicker to place reinforcement steel and concrete, by permitting unobstructed access from above

Suitable products

Edge protection system XP

Doka Safety Systems

This system is the universal safety solution for all edge protection needs. It fits in ideally with …

Guard rails

Doka Safety Systems

These tried-and-tested systems give your site crew optimum protection and make a significant contrib…

Ladder system XS

Doka Safety Systems

System-based ladderways with integral ladder cages can be attached to Doka wall and column formwork …

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.