Framed formwork Framax Xlife

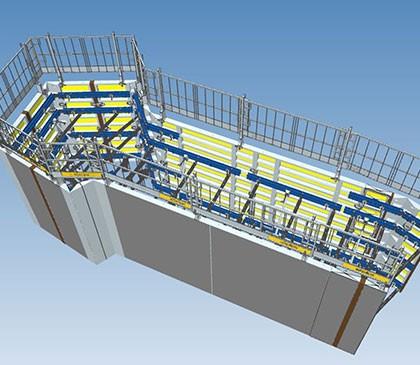

The high-performing steel-framed formwork for crane-assisted forming of large areas

- high numbers of repeat uses made possible by its excellent manufacturing quality and extra-durable Xlife-sheet

- smaller number of (expensive) closure zones, due to the consistent 15 cm increment grid

- the widely spaced form-ties (1.35 m apart) save up to twelve percent of the costs for ties and finishing-work on tie-holes

- galvanised, powder-coated steel frame, for long lifespan

- compact gang-forms mean less crane time is required

- using the single-side-operable tying system Monotec optimises workflows in confined spaces as well

- forming-times are kept short by the widely spaced form-ties (up to 1.35 m apart)

- rapid forming possible thanks to large-area gangs or extra-large panels

- with a high-pressure washer, final and intermediate cleaning is easy, thanks to the panels' powder-coated frames and sturdy timber-plastic composite sheets

- the ingeniously co-ordinated panel formats, with their logical size-grid, help you make optimum use of formwork commissioning quantities

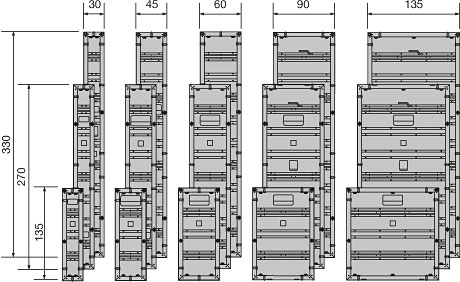

- having only five panel widths makes for easy planning and forming, and efficient logistics

- clean concrete finish from the high-grade Xlife sheet with its plastic-enhanced surface

- the ingeniously co-ordinated panel size-grid permits a neat joint pattern even when combining upright and horizontal panels

- no screw imprints in the concrete, as the formwork sheet is screwed on from the rear

- the neat negative frame-imprints in the concrete minimise any finishing-work

- safe vertical access with the Ladder system XS

- workplace safety on all sides with the Platform system Xsafe plus

- practical accessories – such as panel struts, lifting/repositioning devices, 3-in-1 pole tool etc. – make for safe, easy handling of the formwork

References

System

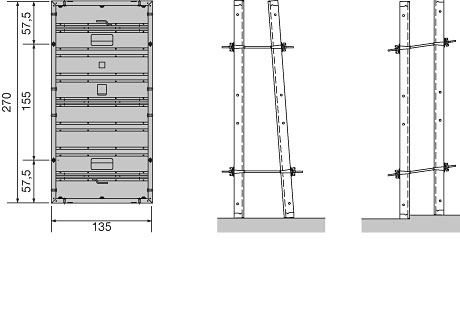

Framax Xlife

- The ingeniously co-ordinated panel formats let you get the greatest possible use out of the formwork

- 15 cm grid, achieved with only five widths and three heights, simplifies planning, forming and logistics on the site

- the frames come with practical cross boreholes that simplify work on stop-ends, corners and columns

- stable galvanised powder-coated steel frames ensure plane concrete surfaces

Framax Xlife sheet

- very high numbers of re-use cycles possible, thanks to plastic-enhanced surface and special sheet structure

- fewer positive imprints, due to the sheet's great resistance to scratching and vibrator damage

- fewer areas needing repair, as there is no splintering and far less swelling around nail-holes

- easy, fast (intermediate) cleaning, also using high-pressure washer

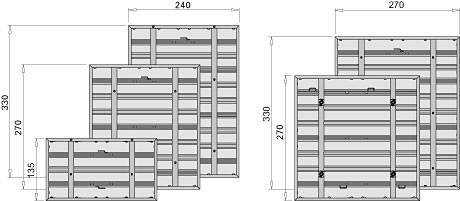

Framax extra-large panels

- for large-area formwork units, meaning fewer inter-panel connections and short repositioning times

- the panels can be used facing one another in the upright

- the large-area elements are especially suitable for producing fair-faced concrete

Shaft formwork with Framax stripping corner I

The Framax stripping corner I was designed specifically for use with shaft formwork. It enables the formwork to be closed and opened in accordance with accident protection regulations, i.e. without using the crane, simply by operating easy-to-turn spindles with a reinforcement rod or the convenient ratchet. It is then lifted and reset in one piece, thus saving crane-time. The Framax stripping corner I is also suitable for use on pilasters and as an inside corner on wall formwork.

Closures

With its 15 cm clamping range, the Framax multi-function clamp matches the panel size-grid exactly. This means that only one closure is needed per wall plane.

Framax 3-in-1 pole tool

For operating the lifting hook safely from ground level, for plumbing and aligning the formwork and for pulling out double-headed nails.

Universal panel SCC

This makes it possible to place self-compacting concrete (SCC) by pumping it into the formwork from below. It can be used for both walls and stop-ends.

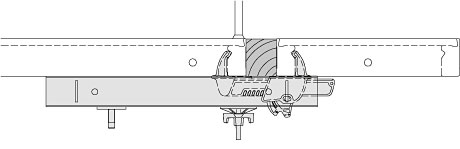

Tying

The wide form-tie spacing of up to 1.35 m delivers huge cost-savings. The large, conical form-tie sleeves in the panels enable them to be stood at an angle on one or both sides, and to be height-mismatched.

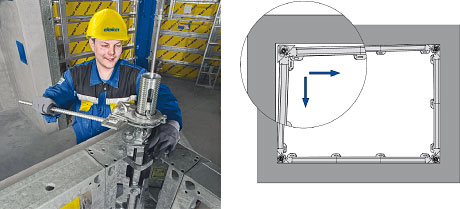

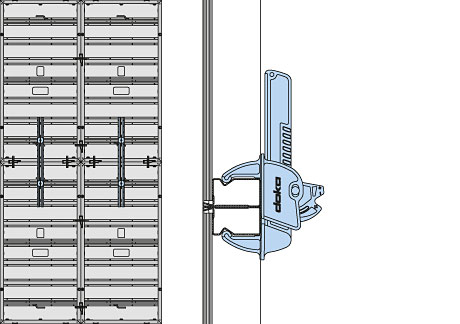

Monotec tying system

Allows form-tie points to be prepared quickly and reliably by just one man. This ergonomically comfortable option for manipulating the ties from just one side of the formwork saves time, and thus shortens the forming-times.

Fitting the Monotec tying system

The combination nut is both the panel connector and the form-tie nut. It holds the panels together on the side that is put up first. On the extra-large panels, the form-tie nuts are bolted onto the frame profile. After the formwork has been closed, the Monotec ties are fitted from one side and tightened with the Monotec ratchet.

Wall thicknesses with Monotec tying system

Only two different types of conical Monotec tie are needed for economically forming wall thicknesses of between 15 cm and 35 cm.

Utilisation

Integrated waling system

Connector-rails across the entire width of the panel make quick and easy work of attaching accessories like panel struts, universal walings and pouring platforms, with no obligatory fixing points.

Joining

A blow of the hammer is all it takes to join the elements. This makes for fast working, with no need for any additional tools.

Vertical stacking

Up to a panel height of 5.40 m, the multi-function clamp, with its larger contact surface, ensures self-aligning inter-panel connections. For higher vertically stacked gangs than this, Universal walings are used to give the gang-form extra rigidity. This makes it possible to put up and set down larger gang-forms by crane.

End-shuttering

The special hole-grid in Framax Xlife universal panels makes them ideally suitable for cost-saving forming of outside corners, wall junctions, stop-ends and columns.

Corners and junctions

Corners at any angle, stop-ends and T-junctions can all be formed swiftly and dependably using the inside corners, hinged corners and versatile Universal panel from the Framax "construction kit". This is the way to avoid costly field-built solutions.

Working safely, with the Platform system Xsafe plus

These pre-assembled, fold-out working platforms, with their integral front/rear and side railings, ladders and self-closing manhole lids, are ready for immediate use and bring about decisive improvements in workplace safety.

Often searched:

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.