Dokamatic table

The safe tableform for fast forming

- shortens build-times and cuts assembly costs because complete units can be repositioned

- horizontal repositioning can be handled by just one person, with the highly manoeuvrable 'DoKart plus' shifting device

- vertical repositioning using the climbing Table Lifting System TLS, independently of the wind conditions, frees up the crane for other uses

- infill zones can be integrated into the system by using insertion beams

- intelligent constructional design permits continuous transitioning to Dokaflex

- easily relocatable swivel heads for adapting to different floor thicknesses

- versatile, as it can be shored using either floor props, table frames or load-bearing towers

- integrable table platforms mean there is no need for work and protection platforms

- pre-planned system solutions make quick work of forming drop beams and stop-ends

- swivel-mounted floor props make it easy to move the tables out over parapets

- high load capacity, achieved by rigid restraint of the floor props

![]()

Fast construction workflows without the crane: with the Table Lifting System TLS, tableforms are brought up to the next floor at the push of a button.

References

System

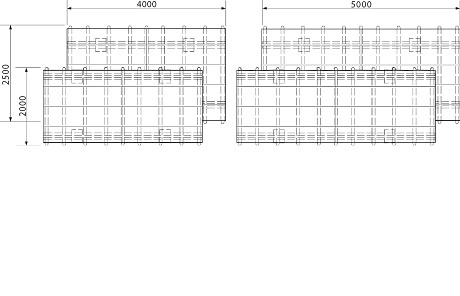

System dimensions with a 'grid' logic

- available in four rentable standard formats with an underlying 'grid' logic: 4.00 m x 2.00 m, 4.00 m x 2.50 m, 5.00 m x 2.00 m, 5.00 m x 2.50 m

- pre-assembled table grille for facing with any desired form-ply

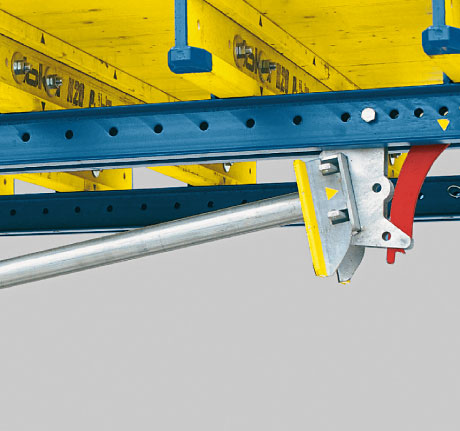

Dokamatic swivel-head 40

- rigid restraint of floor prop for a 10 kN increase in load-bearing capacity

- floor prop can be swivelled and locked in one working position and two idle positions, for safe, fast working

- the swivel-head is easy to relocate in the steel primary beam, for optimally adapting the tables to each structure

- high capacity (slab thicknesses of up to 84 cm) despite the low dead weight of approx. 55 kg/m²

Strong system components for reducing your close-out costs

With their field-proven 'top' quality, the Doka formwork sheets, 'H20 top' beams and 'Eurex top' props ensure reliability and a long service life. The flexurally rigid link with the tableform superstructure increases the load capacity of the 'Eurex top' floor props by 10 kN – from 20 kN to 30 kN in the case of a 'Eurex 20 top' prop, and from 30 kN to 40 kN in the case of a 'Eurex 30 top' prop.

Adapting the props

Some simple steps and just a few blows of the hammer are all it takes to fix, change or remove the props. The integrated quick-acting prop connector makes it possible to adapt the tableforms very quickly to all different jobsite tasks.

Tilting back the props...

The tilting mechanism of the Dokamatic swivel-head 40 is very easy to operate.

...including locking function

To enable the tables to be lifted out across parapets and railings unobstructed, the props can be locked at an angle of either 75° (as shown in picture) or 90°.

Utilisation

Integrated closures

for reducing labour and equipment costs

- Dokamatic insertion beams are used to integrate infill zones into the system. These insertion beams are pushed in or out as needed, and provide the support surfaces for the formwork sheeting.

- The infill zones and the tables are repositioned together, which saves even more time.

Safety around floor-slab edges

- the Dokamatic table platform is fixed directly onto the Dokamatic table, for high workplace safety

- the fold-down railings on the Dokamatic table platform allow the Dokamatic table to be moved in under already-cast slabs, and to be shifted in one piece with the platform

- safe platforms with widths of up to 1.50 m

No need for extra working and protection platforms

The Dokamatic table platforms are located directly on the work-deck level, so they provide high safety. This does away with the need for extra working and protection platforms on the building – and for the erection work that this would require.

Height adjustment

For slab heights of up to approx. 7.00 m, the applicational range of the Dokamatic table can be extended by 1.50 m with the Dokamatic table frame. For slab heights of over 7.00 m, the Dokamatic table can easily be combined with the Load-bearing tower Staxo 40 or the Load-bearing tower Staxo 100.

Integral adaptation at slab-edges

- simple, fast forming of downstand beams with the Dokamatic floor beam plate, for shifting the downstand-beam formwork and the Dokamatic table in one piece

- the floor beam plate lets you form downstand beams of up to 60 cm in height (in a 5 cm grid)

Logistics and transport

Thanks to their compact design, the Dokamatic tables can be loaded onto a truck on top of one another in a very space-saving way, making for improved logistics and reduced shipping costs.

Suitable products

Edge protection system XP

Doka Safety Systems

This system is the universal safety solution for all edge protection needs. It fits in ideally with …

Guard rails

Doka Safety Systems

These tried-and-tested systems give your site crew optimum protection and make a significant contrib…

Sealings for fair-faced concrete

Doka System Components

Reliably casting concrete surfaces in the desired fair-faced concrete category is quite a challenge,…

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.