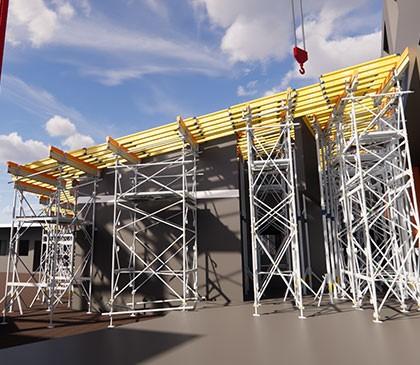

Load-bearing tower Staxo 40

The lightweight shoring system for the building construction field

- wide-area assembly decks with planking units inside the towers and also between the towers

- horizontal pre-assembly possible thanks to crane-handling-safe connections between the frames

- sturdy ladderways

- tested anchorage points for personal fall arrest systems

- high-speed assembly, as there are only a few separate components, all of them very light in weight

- ergonomically engineered H-frames – easier to carry, quicker to set up

- the ability to travel and lift entire towers, instead of labour-intensively dismantling them first

- colour-coded diagonal crossbraces so that you can quickly tell which length is which

- screw-jack U-heads and feet with a 70 cm extension range for easier height adjustment

- shifting-wheels for relocating entire towers, to facilitate an efficient construction workflow

- safely sustains loads at slab-edges by means of brackets

- ease of handling, logical assembly sequence and high-speed working

References

System

Staxo 40 frames

- ergonomically shaped H-frame geometry with low dead weight for easy handling and short assembly times

- sturdy, galvanised H-frames with heights of 0.90 m, 1.20 m and 1.80 m for easy and cost-efficient height adjustment

- defined anchorage points for personal fall arrest systems (PFAS)

Diagonal crosses

- different lengths for variable inter-frame spacing in 50-cm increments from 1.00 m to 3.00 m

- fixed to the load-bearing tower safely and quickly with innovative safety catches

- clear identification of lengths through coloured clips and imprint

Built-in system safety

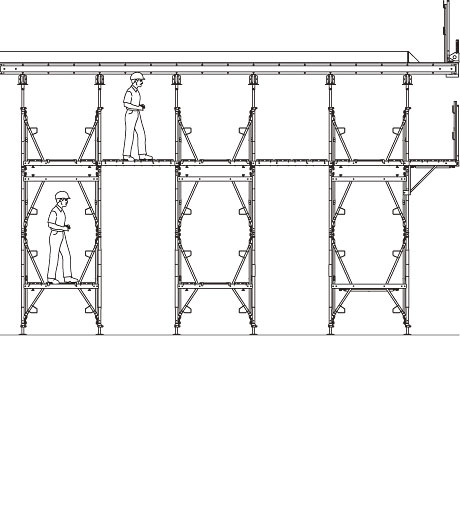

- ladder system with non-skid rungs available for any combination of frames

- anchorage point for personal protective equipment (PPE) anywhere on the frame's diagonals

Plane decking levels with scaffold planking

for quickly and safely erecting and dismantling the superstructure

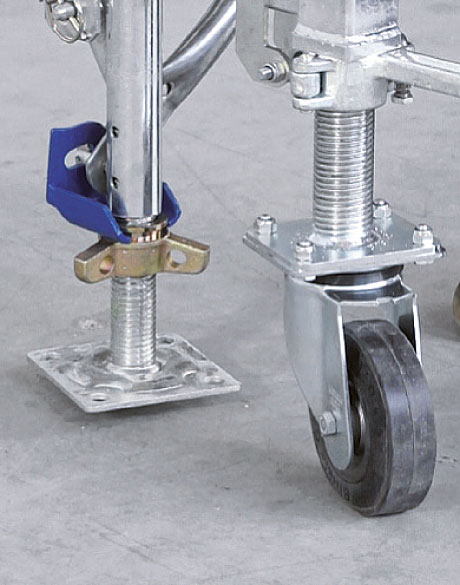

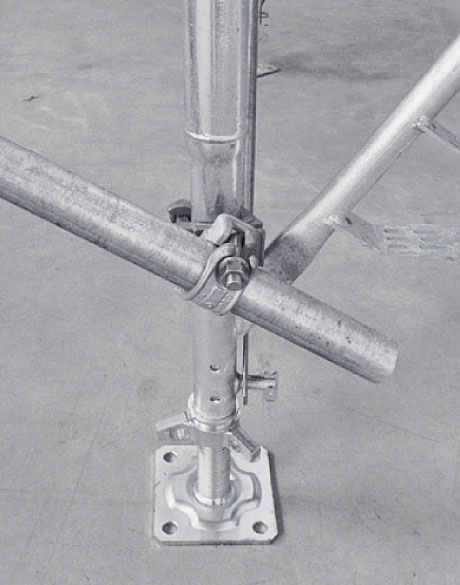

Screw-jack heads and feet

- extension lengths of 70 cm (at top and bottom) for a total of 140 cm adjustment to changes of level and to inclinations

- precision adjustment, right down to the last millimetre, even when under load

- three-wing spindle nut makes for easy height adjustment and rapid screw-jack release

- easy to release, using either a formwork hammer or a reinforcement rod

Utilisation

Efficient and safe erection

- its lightweight, ergonomic components make for an effortless set-up without a crane

- can be erected in the upright with scaffold planking units, 'move-up' railings and available add-on ladderways for high workplace safety

- optional assembly in the horizontal for high workplace safety

Tower-to-tower walkway openings

for fast, safe working inside the scaffold and beneath the towerframe superstructure

Safe working at the edge of the floor-slab

by mounting platform brackets to the towerframes

Cantilevering concrete loads transferred safely

by the high load capacity of the platform brackets combined with a plumbing strut

Craneless horizontal repositioning

with clamp-on shifting-wheels – a simple, sturdy solution that can quickly be connected to the tower

Connecting up scaffold tubes

Scaffold tubes can be connected to every frame, using standard couplers

Getting inside the towerframes is made easy

by the geometry of the Staxo 40 frames

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.