Shoring systems

Doka shoring systems are designed for flexibility, outstanding cost-efficiency and optimum workplace safety, all of which make for fast and efficient forming operations. With its highcapacity shoring systems for the building-construction and civil-engineering fields, highly adaptable forming carriages for bridge-building, and cost-saving tunnel formwork, Doka has the right solution for every requirement.

- result(s):

- result(s):

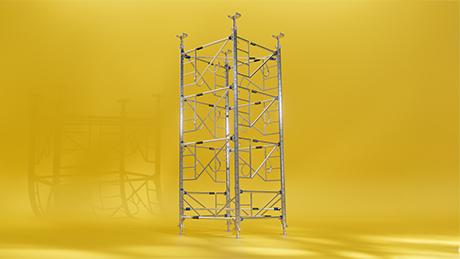

![Load-bearing tower Staxo 100]()

With its robust steel frames, Staxo 100 is designed for large shoring-heights and high loads. It combines high load capa...

![DokaXshore]()

DokaXshore unites frame stability with flexible geometry – just 4 parts per level, tool-free assembly, and a 100 kN load...

![Doka UniKit]()

Doka UniKit - the universal engineering kit for heavy loads in the infrastructure sector. Whether for bridge, tunnel or ...

![Load-bearing tower Staxo 40]()

The lightweight shoring system for the building construction field

![Heavy-duty supporting system DokaShore]()

The extra-high-capacity cost-saving shoring system for heavy loads

![Load-bearing tower d3]()

The high-performing and especially cost-effective shoring system for a wide range of applications

No results found. The search covers names of Doka products and services.