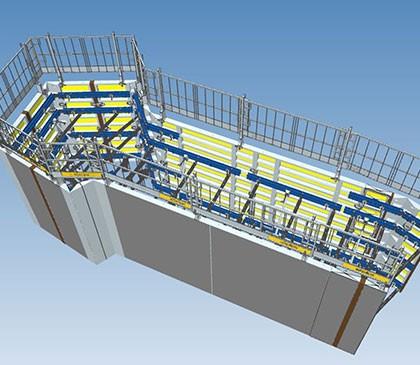

- up to 100 kN load capacity per leg

- excellent weight-to-capacity ratio

- high stability, due to its 1.52 m wide frames

- integrated ladders with non-slip rungs

- integrated tying points for personal fall protection system

- Fast assembly with built-in connectors without

- additional tools

- quick and safe horizontal assembly on the ground with 4 basic components only

- adaptable to different layouts due to variable inter-frame spacing from 0.6 to 3.0 m

- height adaptation and fine adjustment to the millimeter

- full side protection and interconnected towers via walkways

- ergonomic working heights ensured by bracket position adjustment in a 35 cm grid

- significant time saving during superstructure erection.

- Closure decking offers grid flexibility and allows the tower and platform to be shifted together

References

System

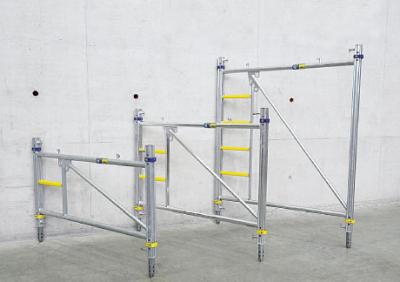

Staxo 100 frames

- extremely robust steel frames available in 0.90 m, 1.20 m, and 1.80 m height for simple height adaptation

- built-in connectors make the system easy to set up

- safety catches for fast and safe diagonal cross assembly

- integral ladders with non-skid rungs

- defined attachment points for Personal protective equipment

- easily connected to frame tubing couplings

![Staxo 100 steel frames in different sizes]()

![Colour-coded Staxo 100 diagonal crosses]()

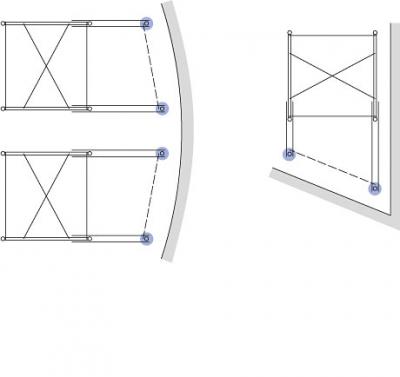

Diagonal crosses

- the firmly connected diagonal braces make the system quick and simple to erect

- different lengths of diagonal cross permit flexible inter-frame spacing, for cost-optimising the load capacity

- unmistakable length identification provided by colour-coded clips and embossed markings

Screw-jack heads and feet

- height adjustment possible right down to the last millimetre

- easy to operate, thanks to special thread geometry and integral fixing handle

- can be released with minimal physical effort, even when under load

![Screw-jack heads and feet]()

![Heavy duty screw-jack extension]()

Heavy duty screw jack

The screw-jack extension length of up to 2 m per load-bearing tower permits optimum adaptation to changes in the level of the support base, to downstand beams and to sloping slabs.

Very high workplace safety

- 'mounted-ahead' railings for erecting and dismantling the towerframes safely when this is done with the tower in the upright

- toeboard for safe workplaces e.g. beneath the towerframe superstructure

- a mounting-gallows makes it easy to pull up the towerframes

![Worker climbing up a ladder]()

![Example illustration of the possible adaption to unusual layouts]()

Added single legs

- for easy adaptation to unusual layouts

- continuous positioning possible up to 1.50 m away from the tower

- optimised equipment utilisation

Scaffold planking units

- for safety while assembling and working inside the scaffold

- lightweight aluminium or timber decking (width: 60 cm) with manhole and sturdy steel decking (width: 30 cm)

- at least two decking units (60 cm) needed on each storey of load-bearing tower

- integrated anti-liftout guard allows scaffold planking units to be added even when the load-bearing towers are pre-assembled in the horizontal

![Worker climbing up a scaffold planking unit]()

Utilisation

Simple and fast vertical stacking

- with few individual parts for simple use

- as connection sleeves and connecting pins are integrated in the frames

- thanks to logical set-up sequence

- because diagonal crosses are all clearly and unmistakably identified with colour-coded clips

![Worker connecting two parts of the frame]()

![Worker adjusting the screw-jack head]()

Continuous height adjustment

- using the easy-to-operate screw-jack heads and feet for last-millimetre adjustment even when under load

- with a 2 m jack extension length per tower when the extra-strong Staxo 100 heavy duty screw jack is used

Stair tower

By combining standard Staxo 100 frames and pre-assembled aluminium stairway elements, this provides safe access to high-up workplaces.

![Stair tower reaching multiple floors of a high-up workplace]()

![Forklift truck repositioning a load-bearing tower Staxo 100]()

Assembly using forklift truck or telescoping stacker truck

with this safe and effort-saving method, load-bearing towers are safely erected and dismantled in the upright as well as repositioned

Adaptation to unusual layouts

by combining the towers with single legs

![Tower adapted to an unusual layout]()

![Worker safely installing a load-bearing tower]()

Erecting towers in the upright

with 'mounted-ahead' railings and scaffold planking units with manholes, for high safety

Fast and safe repositioning

using winches, Shifting carriages TG or forklift trucks

![Worker easily repositioning a load-bearing tower]()

![Worker assembling a load-bearing tower in the horizontal]()

Erecting towers in the horizontal

a safe, fast method of erecting the towers

Suitable products

Stair tower 250

Doka Safety Systems

The sturdy, stable stair tower can be put together very quickly from frames and pre-assembled stairw…

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.