![Icon Stations and lines]()

Stations and lines

![Icon Mining method]()

Mining method

![Icon Cut-and-cover method]()

Cut-and-cover method

- Less assembly work, because small number of shoring frames due to statically optimised load-bearing system

- Less work due to small number of operating points

- The optimised V-strut angles ensure high safety against overturning or slippage of the wall foundation

- Safe up/down access via integrated caged ladderway

- Large drive-through access openings for site traffic

- Clearly structured documentation from assembly drawings through to risk assessment

- CE mark is standard in Europe

- Hydraulic lifting appliance for easy lifting, lowering and precision-adjustment of the forming wagon - manual operation is also an option

- Optimised travelling structure for repositioning without adaptation

- Optional: Short set-up times, because components of formwork and load-bearing systems are pre-assembled

Formwork and expertise from a single source

Doka is your full-service partner on complex tunnel projects – from planning through project management to solutions that work – everything from a single source.

![People working on a complex tunnel project]()

![Innovative tunnel system in use]()

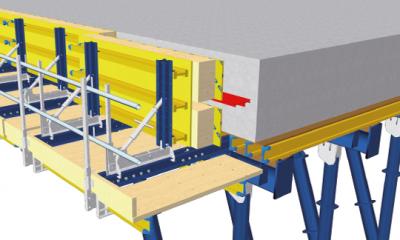

Innovative system design

System can be used on foundations of all types.

Practical stop-end formwork

Large platforms allow sufficient stripping paths

![Rendering of stop-end formwork]()

![Forming wagon on rails]()

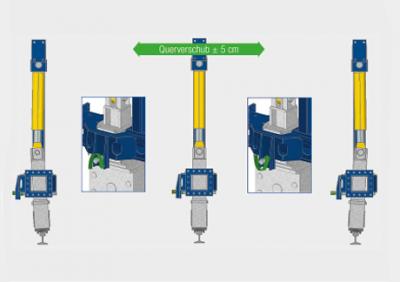

Safe to use

The innovative design ensures that the forming wagon remains securely on the rails, no issues with derailing even during lateral shifting.

Quick and easy repositioning

The hydraulic lifting appliance makes it easy to lift, lower and precision-adjust the forming wagon.

![Illustration of the hydraulic lifting appliance]()

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.