Framed formwork Frami Xlife

The crane-independent manhandled steel-framed formwork for foundations, walls and columns

- handy steel-framed formwork for foundations, walls and columns

- easy to manhandle, yet sturdy enough for large-area forming, also with a low-load crane

- its wide range of different tying options shortens forming-times

- its self-aligning panel connectors mean that no extra stiffening reinforcements are required

- high numbers of repeat uses made possible by its excellent manufacturing quality and extra-durable Xlife-sheet

- extensive safety and workplace accessories such as plumbing accessories, working platforms and self-aligning panel connectors

- smaller number of (expensive) closure zones, due to the consistent 15 cm increment grid

- efficient forming of shafts aided by seamless connection to Framax stripping corner I

- long lifespan achieved by quality hot-dip galvanised steel frame

- the ingeniously co-ordinated panel widths, and the facility for continuously height-mismatching the panels, permit optimum adaptation to any structure

- Universal panel with hole grid makes it easy to form columns, stop-ends and wall junctions

- having only five panel widths makes for easy planning and forming, and efficient logistics

- with a high-pressure washer, final and intermediate cleaning is easy, thanks to the panels' hot-dip galvanised frames and sturdy timber-plastic composite sheets

- clean concrete finish from the high-grade Xlife sheet with its plastic-enhanced surface

- the ingeniously co-ordinated panel formats permit a neat joint pattern even when combining upright and horizontal panels

- the high-load-capacity formwork sheet and statically optimised frame profile facilitate plane concrete surfaces

- the neat negative frame-imprints in the concrete minimise any finishing-work

- safe vertical access with the Ladder system XS

- workplace safety on all sides with the Frami pouring platform

- practical accessories – such as panel struts, lifting hook etc. – make for safe, easy handling of the formwork

References

System

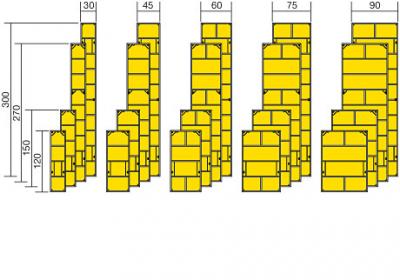

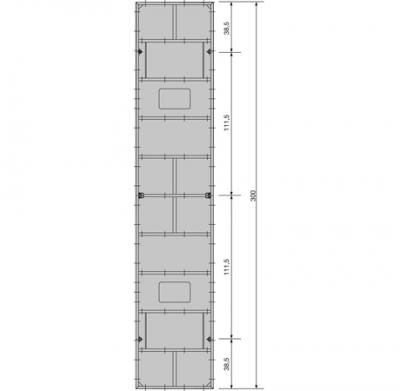

Logical system grid

- logical system grid in heights of 1.20 m, 1.50 m, 2.70 m and 3.00 m, and widths of 30 cm to 90 cm, in 15 cm increments, for optimum adaptability to the structure

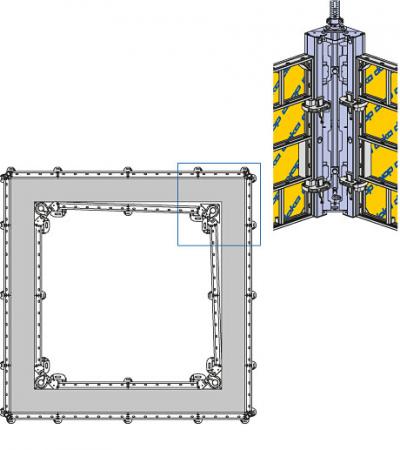

- 75 cm or 90 cm wide Universal panels with hole grids for stop-ends, outside corners and columns

- larger gang-forms can be stiffened with aligning clamps or universal walings, allowing them to be repositioned quickly and easily by crane

![Framed formwork Frami Xlife]()

![Feuerverzinkte Rahmen, Xlife-Platte]()

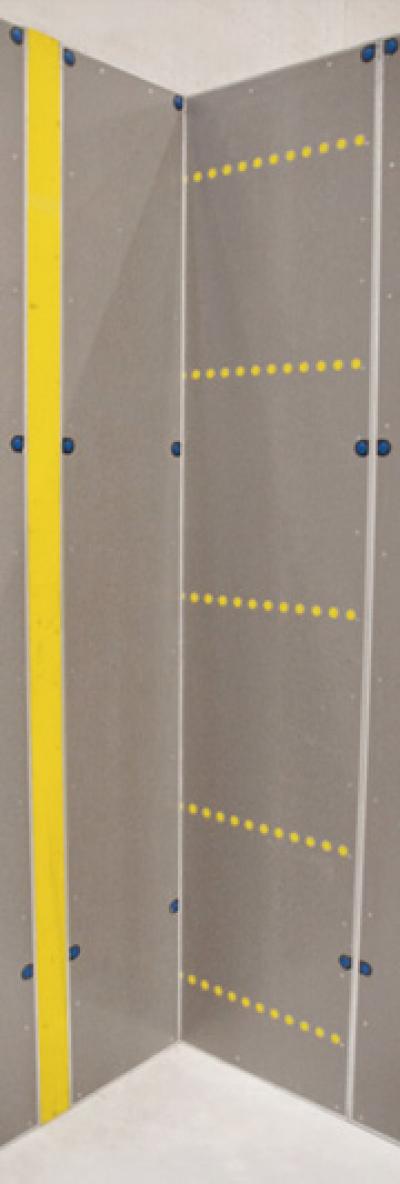

Hot-dip galvanised frames, Xlife sheet

The frames of the panels are made of hard-wearing hollow steel profiles and are torsion-proof with no need for any extra stiffening. Their premium hot-dip galvanised finish gives them a particularly long lifespan. The Frami Xlife sheet delivers high numbers of re-use cycles, with outstanding concreting results. Its special surface structure prevents splintering and swelling caused by nail-holes.

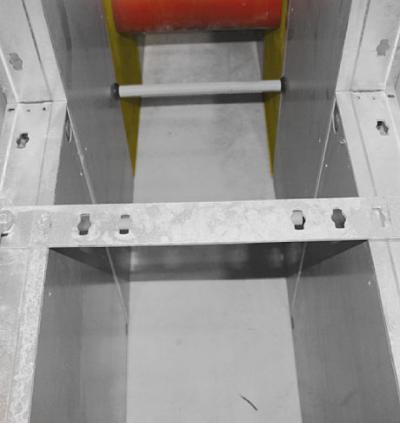

Frami clamp

Just one blow of the hammer on the Frami clamp is all it takes to pull the panels together and achieve a flush, correctly aligned panel joint that is resistant to tensile forces.

![Frami-Spanner]()

![Stufenloser Höhenversatz]()

Continuous height mismatch

The continuous hardware slot in the frame means that the Frami clamp can be fixed anywhere on the frame. Because of this, the panels can be continuously height mismatched, i.e. without any pre-defined grid. This means that the formwork can easily be accommodated to e.g. steps, slopes and uneven ground, with no extra work.

The Frami Xlife universal panels permit right-angled corners up to wall thicknesses of 60 cm, in a 5 cm grid.

![Frami universalelemente]()

![Winkel Frami xlife]()

Obtuse and acute-angled corners are formed using the galvanised Frami hinged inside corners.

With its 15 cm clamping range, the Frami adjustable clamp exactly matches the panel size-grid. This means that only one closure is needed per wall plane.

![Frami-ausgleichsspanner]()

![Frami-ankerhaltwinkel]()

The Frami anchoring bracket relocates the top form-tie above the panel, which makes it easier to strike off the concrete.

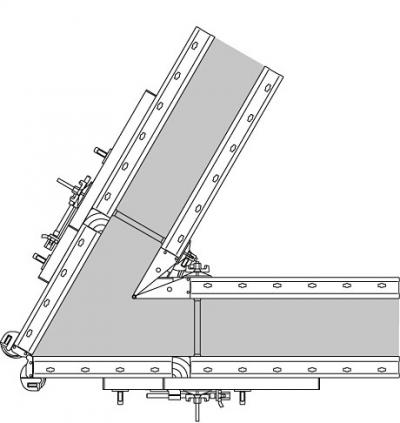

Foundation anchoring system consisting of a flat tie-rod and a foundation clamp, for wall thicknesses of between 10 cm and 80 cm in a 5 cm grid – without any ties placed through the concrete and without any supporting timbers.

![Fundamentankersystem]()

![fundamentspanner]()

The bottom of the panel is fixed by foundation clamps and by a perforated tape with a 5 cm grid.

Utilisation

Polygonal circular formwork

The circular forming plate extends the applicational range of the panels to take in polygonal curves: an economical solution where the curve of the wall does not need to be strictly circular.

![Polygonale Rundschalung]()

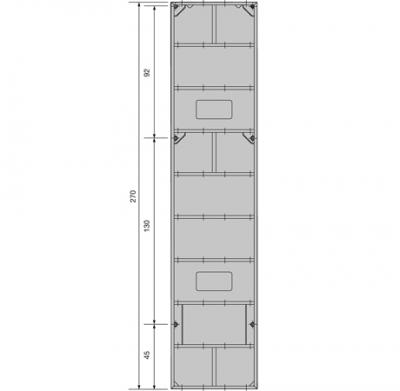

Room-high panels

Die robuste Konstruktion und die asymmetrische Anordnung der Anker erlauben bei 270 cm hohen Elementen den vollen hydrostatischen Betondruck.

![Raumhohe Elemente]()

![300cm-Elemente]()

Only three form-ties are needed per 300 cm height of panel.

An extensive range of accessories ensures safety during pouring, even for room heights of 2.70 m or 3.00 m that are poured in one continuous operation.

![Zubehör]()

![Lochreaster]()

The special hole-grid of the 75 cm and 90 cm wide Frami Xlife universal panels makes them suitable for economical forming of stop-ends, outside corners and columns.

Foundations

Placed on their sides, Frami Xlife panels are ideal for cost-saving forming of foundations.

![Fundamente]()

![Schachtschalung]()

High-speed shaft formwork

Using profile adapters, the Frami Xlife panels can easily be combined with the Framax stripping corner I

Questions about Frami Xlife? Write to us.

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.