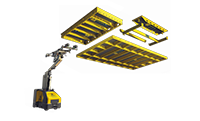

DokaXdek dekkebord.

Den nye dimensjonen

av plass-støpte dekker.Lengde x Bredde x økonomi

*Kunstnerisk presentasjon .

DokaXdek system ![DokaXdek system]()

DokaXdek kassettdekke ![DokaXdek panel]()

DokaXdek dekkebord. Lengde x Bredde x økonomi

DokaXdek-bordet er det sterke medlemet av DokaXdek-familien og passer for store og mellomstore byggeplasser. Med elementer på inntil 12,5m² er DokaXdek-bordet spesielt fordelaktig for dekning av store dekkeflater. Takket være den galvaniserte stålrammen og Xlife finèr, er DokaXdek-bordet svært slitesterkt og lett å rengjøre. Overgangen til DokaXdek-håndsystemene og Dokaflex er sømløs.

Møt DokaXdek-familien!

DokaXdek kassettdekke

Lengde × Bredde × Fleksibilitet

![DokaXdek element]()

Det raske og sikre forskalingssystemet for fleksibel bruk på alt fra eneboliger til store byggeplasser.

Finn ut mer DokaXdek-I ramme*

Lengde x Bredde x Ergonomi

![DokaXdek frame]()

Ergonomic and lightweight all-rounder

*DokaXdek-I frame is a demo version.

Under utvikling DokaXbot*

Lengde x Bredde x Automatisering

![DokaXbot]()

Halvautomatisk og sikker forskaling og utstøping av DokaXdek etasjeskillere og DokaXdek I-rammer

*DokaXbot er en demoversjon .

Under utvikling En gjennomtenkt løsning hele veien.

![DokaXdek table detail]()

![DokaXdek table detail]()

![DokaXdek table detail]()

Har du spørsmål om DokaXdek? Skriv til oss.

Ofte søkt på:

Applikasjonsvideoer

Dokumenter og nedlastinger

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

Ingen resultater funnet.