Cooling-tower formwork SK175

The self-climbing formwork for cooling towers

Safety in all phases of the work

- even at great heights in strong winds, as the formwork is always firmly attached to the structure

- due to its telescopic working platforms – these are railed-in and gapless even while climbing is in progress, and so provide a safe working environment at all times

- thanks to optimally adapted platform widths and integrated ladder systems

Optimised formwork concept for fast forming-times

- large-area formwork gangs, making the system much simpler to operate and clean

- as the inclination of the whole scaffold can easily be adjusted from one central spindle

- thanks to the built-in reinforcement holders in the scaffold, which make it a quick and easy job to place the reinforcement

A cost-effective solution is facilitated by

- all-round platforms that allow operational sequences to be 'de-linked'

- a very small number of form-tie points per square metre

- consistently high concrete quality, thanks to the steel form-facing

- large-area formwork gangs for a casting-section height of 1.50 m

- the practice-oriented project planning provided by Doka

References

System

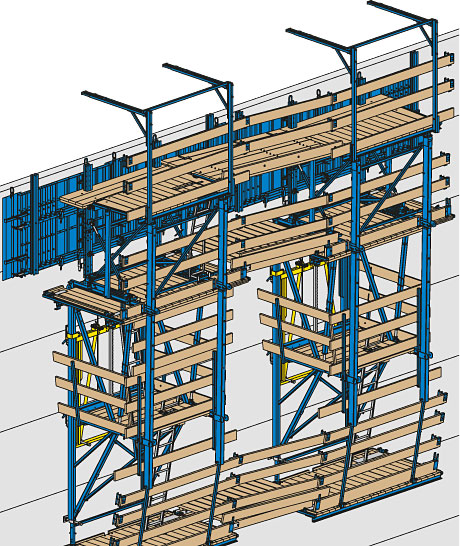

Cooling-tower formwork SK175

This special cooling-tower formwork for hyperparaboloidal natural draught cooling towers was developed in the course of several years' work on the basis of the Automatic climber SK175. The high capability of this system has been confirmed by its use on very many construction sites.

The platform system for a streamlined workflow

The permanently mounted telescopic platforms ensure that there is an uninterrupted circumferential walkway all the way around the cooling tower at all times, even during the entire climbing operation. This detail makes a crucial contribution towards safe – and thus troublefree – working.

Utilisation

High adaptability

Down to a vertical radius of 70 m, the cooling-tower formwork can climb through curves unhindered. Up to a 22° angle of inclination, the formwork is adjusted simply by the platform system, with one spindle per bracket.

Placing the reinforcement

Working from the top platform, the reinforcement can be placed a day in advance. The reinforcements are held in position during placement by reinforcement holders mounted on the scaffold.

A well thought-out system

The four platform levels make for a well-ordered construction workflow and safety during all operations.

Electromechanical lifting systems are used to raise the formwork, making it completely independent of the crane.

Steel formwork elements with compensating elements on both sides provide adaptability in the horizontal and make for constant concreting results all the way through to the very last casting section.

To allow the formwork elements to be quickly cleaned, they are designed so that they can be rolled back approx. 60 cm from the concrete. The formwork is opened with the aid of a spindle, and rolled back by hand on rollers.

Suitable products

Edge protection system XP

Doka Safety Systems

This system is the universal safety solution for all edge protection needs. It fits in ideally with …

Ladder system XS

Doka Safety Systems

System-based ladderways with integral ladder cages can be attached to Doka wall and column formwork …

Application Videos