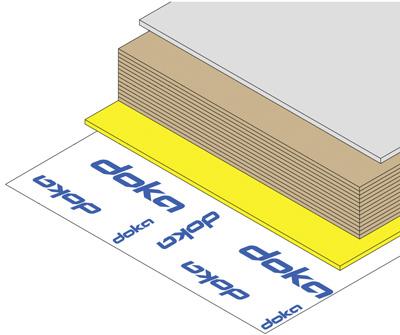

Plywood sheets – formwork panels for concrete forming and other construction applications

Doka is one of the few formwork manufacturers who also produces and distributes plywood sheets for our customers thus helping them optmise overall construction costs, speed and quality of project execution. We provide a diverse and region specific range of plywood sheets to be used for various applications at the construction site. Whether for formwork, infill zones or just to set up the construction site our range of formwork sheets covers many applications and formats. Our comprehensive portfolio of plywood boards and supporting services allows construction project managers to make a smart choice by sourcing the right combination of plywood material depending on its use.

Discover the range of formwork plywood sheets by Doka

Looking for the right plywood sheets for your construction site?

Try the Doka Plywood Selector

You already know what plywood material is required for your project?

Buy online plywood sheets

Short guide to plywood sheets

Types of plywood used in concrete forming and related construction applications

Formwork application requires wooden panels with 3 or more layers of film faced or uncoated plywood. Each type of wood material has its own properties and characteristics that influence the performance of the sheets in concrete application, such as the bending strength and the durability. These characteristics determine the cost of the sheet but also its use cycles – the number of times panels can be used in concrete forming. The more times a sheet can be reused without decreasing its properties and performance, the lower the cost per usage.

Types of materials used for plywood sheets

Usually wooden boards are made of birch, poplar, spruce, or pine but there are many types of materials used by plywood manufacturers in different parts of the world.

While the type of wood used is important, the real opportunity for making a difference for the final concrete result is the type of coating: the film that is applied on the plywood surface. Wood has the natural property to absorb moisture, resulting in a sponge effect. This causes movement of the panels, affects the weight and the mechanical properties of the material, ultimately influencing its life cycle.

Selecting the right type of coating while taking into account the application would determine the consistency of the quality of the concrete and the cost efficiency of the project.

Some of the best film materials for plywood include

- Urea-melamine resin coating

- Plastic coating

- Film coating

- Fibre-reinforced synthetic resin coating

Alternative materials for plywood include full plastic, plastic coated that have higher bending, aluminium.

Application factors affect the choice of plywood sheets

Formwork application

Slab and wall formwork used in commercial, residential and high rise construction often determines the choice of plywood panels to be ordered. Plywood used in slab and wall formwork can wear out more quickly due to the heavy use of floor surfaces or due to the multiple reuse cycles expected for wall formwork. Therefore, it would be wise to invest in more durable panels if you would like to achieve lower cost per use. It has been determined that a higher number of reuses of the plywood would affect the architectural requirements of the resulting concrete surface.

Infrastructural construction projects

By infrastructural projects, such as tunnels and bridges, the building process is the factor that substantially affects the choice of plywood sheets. When continuous flow is important and multiple concrete pouring is planned, the plywood material has to be durable enough to be reused many times (often more than 50).

In bridge construction, there are special factors to consider as well: the need for strong reinforcing, many pouring stages and long periods between the pouring stages. It is crucial to plan for shrinking of the plywood and avoid inappropriately used plywood to affect the quality of the concrete or the duration of the project. Learn more about our expertise for infrastructural projects: bridges, tunnels, power plants and mining

Loose application and supporting construction works

It is easy to overlook some aspects of the construction project where workers end up using plywood material. Real world practice shows that plywood is often used in more simple applications such as the setup of the construction site - temporary constructions assisting the building up, site fences, dust walls used for protection or separation of certain areas of the building, as well as in many other supporting functions.

Rising walls and structures is not always straightforward: different forms, infill areas or box outs complicate the process. In loose application, using the same high-class plywood sheets purchased for the concrete pouring application is not cost effective. There are plywood sheets with no coating or with basic properties that fit perfectly such usage.

Planning for such applications can help you place a smart and cost effective order of plywood material.

Desired surface condition of the finished concrete

By construction projects with very high architectural requirements the plywood would need to possess certain qualities such as durability against scratches and vibrations and large size panels, a very smooth surface, or a surface with a specific pattern. If a plaster or paint has to be applied on a smooth concrete surface the plywood sheets would have to possess certain characteristics.

If the concrete face will be left as it is, you might consider plywood that is specifically manufactured for fair-faced concrete surfaces.

Categorisation of plywood sheets

Plywood sheets comes in a variety of sizes, grades and classes. Choosing the right combination is crucial for the cost effective purchasing of the plywood material.

Categorisation by number of uses (guide value)

- Up to 2 cycles

- 2-10 cycles

- 10 -50 cycles

- 50 -100 cycles

- More than 100 cycles

Categorisation by classes

- Single - limited properties, number of uses and low cost. Example: CUTplex, DokaPly natural

- Middle - a combination of characteristics, up tp 30 use cycles, middle price range. Example: UNIplex, DokaPly eco, 3-S basic

- Top - optimal properties or special case usage, up to 100 use cycles, upper price range. Example: Xface, DokaPly SC/DC, 3-SO

Selecting the right plywood material and planning your order in the most cost efficient way taking into account logistics and purchasing options is not always an easy job. With a supplier who considers plywood as part of the big picture and offers comprehensive solution to purchasing or renting plywood material and formwork, logistics and engineering expertise, you can be confident in the success of your construction project.