Automatic climbing formwork SKE plus

The crane-independent climbing formwork for structures of any shape and height

- as a highly efficient system-based 'construction kit', it can be adapted to any shape of layout and any structure height

- the freely plannable parallel climbing units also make the system suitable for varying wall inclinations and wall-returns

- the practical standard solutions provide ample workspace on shaft formwork units

- fast, weather-shielded working made possible by the large all-round workspace

- several parallel climbing units can be repositioned quickly at the same time, by radio remote-controlled 'pushbutton' climbing

- integrated platforms, stair towers and ladders provide complete safety during working operations and for up-and-down access

- saves on craneage, as payloads can also be raised along with the platforms when these are 'climbed'

- craneless climbing made possible at any time, by all-hydraulic repositioning right from the very first casting step

- optimised construction workflows achieved by flexible cycling of the units for repositioning

References

System

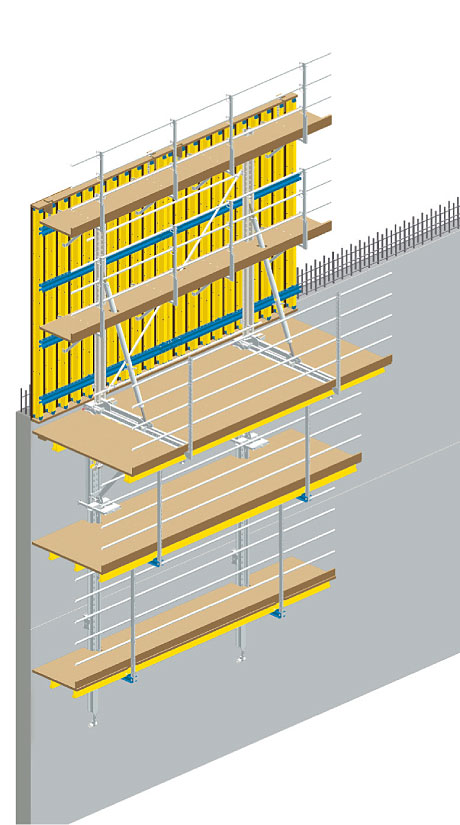

Automatic climbing formwork SKE50 plus

Automatic climbing formwork SKE50 plus, with a load capacity of 5 t per parallel climbing unit, is the ideal solution for many different types of assignment. As well as for forming high-rise cores, industrial structures, bridge piers and pylons, this innovative system can also be used for constructing facades.

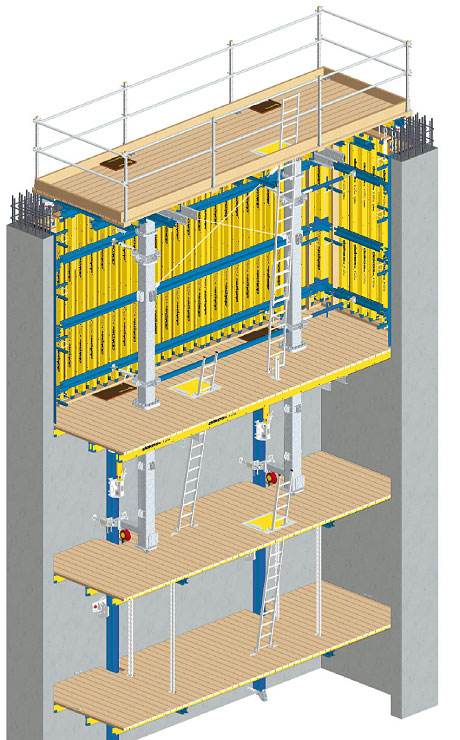

Automatic climbing formwork SKE100 plus

This is the design variant with rising working platforms, enabling work to proceed simultaneously on several levels. This allows the forming and rebar operations to be 'de-linked', so as to shorten the cycle times. The high load capacity of 10 t per climbing unit also makes it possible to reposition extra payloads such as reinforcement steel, containers and concrete placing booms.

Safe choice, right system

Automatic climbing formwork SKE plus is definitely the 'safe' choice of system. Its wide, fully railed-in working platforms, the well thought-out access paths and the gapless-enclosure option all make for a high level of safety at your site. Up to 20 automatic climbers can be raised from one casting section to the next by a single hydraulic unit.

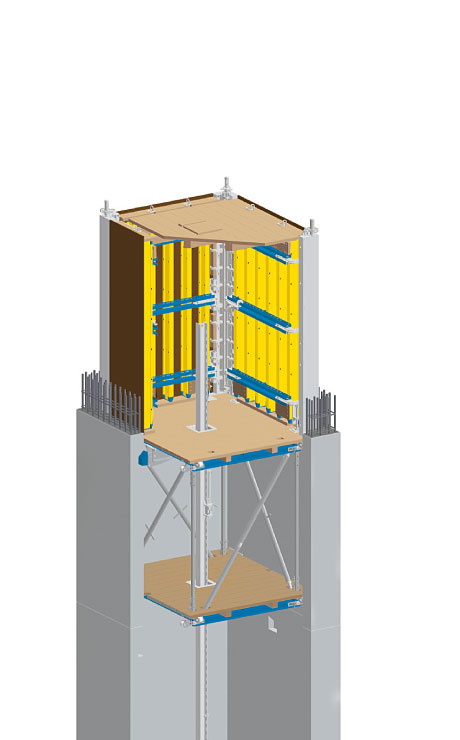

SKE50 plus with shaft system

When inside-shafts need to be formed cranelessly, this shaft system greatly boosts the speed of work. Exact adaptability, straightforward formwork operation, combinability with the Framax stripping corner I, re-useable anchoring components – these are just some of the many advantages of this innovative system.

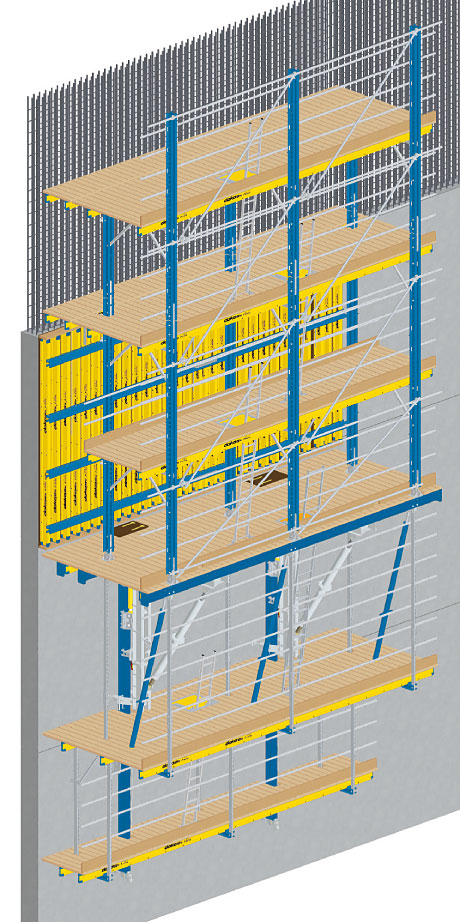

SKE100 plus with mast system

This system combines high load capacity with generous workspace. As the system only needs to be anchored in one wall, the mast system can be used not only in shafts but also for forming simple walls and even 'single-pour' walls + floor-slabs.

Forming narrow shafts

Where space is at a premium – in structures such as the Tour CMA in Marseilles, France – self-climbing systems from Doka are an ideal formwork solution.

Suitable products

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.