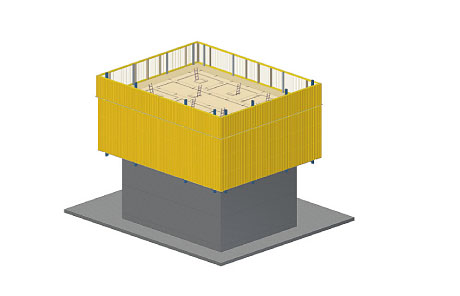

- safe, weather-shielded working made possible by the large, fully enclosed workspace

- prevents fall-hazard locations opening up during repositioning, as the entire platform is raised hydraulically in one lift

- integrated platforms, stair towers and ladders provide complete safety during working operations and for up-and-down access

- quick and easy to reposition in only a few operational steps, as it is 'climbed' at the push of a button

- short forming-times, as the formwork suspended from the girder grille is easy to close and open

- speeds up the workflow, as the crew enjoy an enhanced feeling of safety at all heights

- saves on craneage, as the platform can also transport high payloads, including equipment containers and concrete placing booms, when it climbs

- can be adapted to any requirement, thanks to its modular system and to the fact that there are several different ways of suspension-mounting it to the structure

- optimised construction sequences achieved by the planning and engineering services of the Doka Competence Centre

References

System

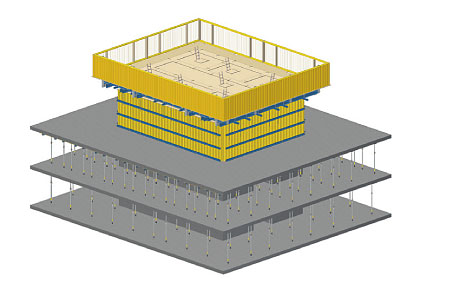

Core climbed ahead

In this construction method, the core zone (lift shafts, stairwells) climbs ahead of the floor-slabs. 'De-linking' the different building components in this way speeds up work, while providing excellent protection against the weather.

Slab and walls cast in one pour

In this construction method, the floor-slabs and walls are cast in one single pour – this makes for high cost-efficiency and speeds up construction progress still further.

Sophisticated logistics, ease of operation

The high service loads that are possible on the Platform SCP save storage space on the site at ground level. For even faster cycle times, the reinforcement operations can also be carried out above the platform. The system makes it possible to suspend working platforms that reach deep down into the shafts, enabling the crew to start carrying out finishing-jobs while the concreting works are still underway.

Utilisation

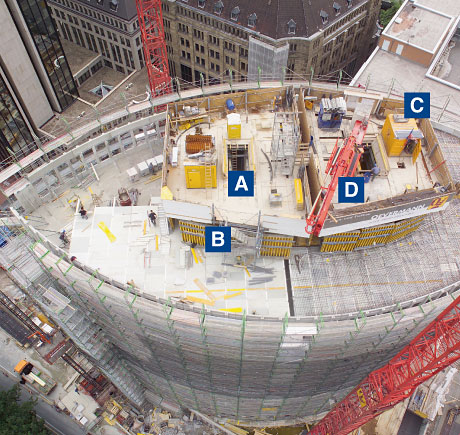

The forming machine

(A) Openings as needed in the working platforms, for equipment-handling or for installing stairways

(B) Safe access routes, thanks to the flexibility with which stair towers can be used

(C) Equipment and tool containers can easily be installed. This optimises the infrastructure.

(D) A concrete placing boom can be integrated into the formwork concept, and raised with the Platform SCP.

Upwards at the push of a button

Together with the working platform, timber-beam or framed formworks are raised to the next casting section in a single lift, by powerful hydraulic cylinders.

Ample space and safety, at any height

The generous striking-distances and ingenious platform system permit "Safe. Fast. Efficient." working, just like on the ground.

Suitable products

Application Videos