Framed Formwork Alu Framax Xlife

The lightweight aluminium framed formwork for forming with or without a crane

- the low panel weight reduces the work-strain associated with hand-set forming, yet the panels have a high load capacity of 60 kN/m²

- the frames are made of torsion-proof hollow aluminium profiles, so can also be shifted by crane

- seamless transitioning to Framax Xlife makes operations easier to break down into crane-handled and man-handled zones, permitting flexible logistics and fast workflow on the site

- high numbers of repeat uses made possible by its excellent manufacturing quality and extra-durable Xlife-sheet

- high load capacity thanks to top-quality forged connector components

- smaller number of (expensive) closure zones, due to the consistent 15 cm increment grid

- using the single-side-operable tying system Monotec optimises workflows in confined spaces as well

- the ingeniously co-ordinated panel formats, with their logical size-grid, help you make optimum use of formwork commissioning quantities

- universal panels, for practical corner configurations and column formworks

- top-quality transparent powder-coating makes for easy cleaning and uniform frame appearance, even after many repeat uses

- fast, easy planning with the Tipos planning software

- clean concrete finish from the high-grade Xlife sheet with its plastic-enhanced surface

- the ingeniously co-ordinated panel formats permit a neat joint pattern even when combining upright and horizontal panels

- no screw imprints in the concrete, as the formwork sheet is screwed on from the rear

- safe vertical access with the Ladder system XS

- workplace safety on all sides with the Platform system Xsafe plus

- practical accessories – such as panel struts, lifting/repositioning devices, 3-in-1 pole tool etc. – make for safe, easy handling of the formwork

System

Alu-Framax Xlife

- ingeniously co-ordinated panel formats, for getting maximum utilisation from the formwork

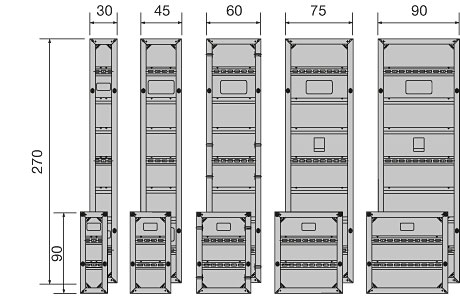

- 15 cm grid, achieved with only five widths and two heights, simplifies planning, forming and logistics on the site

- the high-grade powder-coating on the Alu-Framax Xlife panels reliably prevents concrete adhesion

- integrated waling system: the connection profiles make it easy to attach accessories – with no obligatory fixing points

Framax Xlife sheet

- very high numbers of re-use cycles possible, thanks to plastic-enhanced surface and special sheet structure

- fewer positive imprints, due to the sheet's great resistance to scratching and vibrator damage

- fewer areas needing repair, as there is no splintering and far less swelling around nail-holes

- easy, fast (intermediate) cleaning, also using high-pressure washer

Alu-Framax pallets

The practical Alu-Framax pallets make light work of offloading the panels at the site.

Framax circular forming plate

By combining Framax circular forming plates and Alu-Framax Xlife panels, it is possible to form polygonal curves.

Combining with Framax Xlife

Combining Framax Xlife with Alu-Framax Xlife makes it possible to divide up the site into crane-handled and man-handled zones, making for flexible logistics and a fast workflow on the site.

Universal panel

The 75 cm wide Alu-Framax Xlife universal panel is used for forming columns, stop-ends and corners.

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.

Save time and money:

Buy formwork spares and accessories online.