Doka Xpress CEU 02/2019

Advantages of virtual reality in formwork planning

The use of 3D is almost standard for complex components in formwork planning. In some cases, 4D simulations can also be used: If you play through the construction process using the digital twin in advance, then possible problems, but also opportunities for improvement, that would not have been easily apparent in conventional planning, can already be identified here. During the construction phase of an access ramp for the Arnulfsteg Bridge in Munich, using VR provided exactly these kinds of important insights.

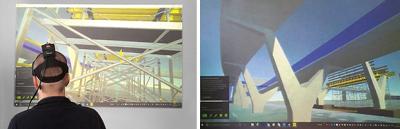

Keeps the eye sharp for picking up details: Use of VR glasses to get a virtual view of the construction site including formwork planning in advance.

"It'll give you a whole different feel for the construction site."

In the future, the Arnulfsteg Bridge, which is approximately 242 m long, 3.50 m high and made of steel, will cross the 37-track railway line of the city. Construction company, Mayerhofer, turned to Doka for formwork planning for the south ramp, including the seven ramp supports and one stairway support. Both the loop-shaped ramp belt and the props had extreme technical demands.

In order to get a better idea of the formwork planning, Doka prepared it in such a way that the foreman and project manager were able to virtually go through the subsequent assembly 1:1 in advance using VR glasses. The two agree that, "It'll give you a whole different feel for the construction site." This also takes planning technology to a completely different level: For example, in the rounding area of the ramp, it became apparent that it would have taken a great deal of time to measure the originally planned formwork variant on site. Instead, Doka proposed an alternative, with higher manufacturing requirements in advance, so that a lot of time could be saved on the construction site itself. “After visualising the situation I was able to compare both options and it was plain to see: it works out better with the prefabricated boxes”, says the foreman. Visualisation also improved the geometry of the three-armed prop.

Project:

South access ramp for the Arnulfsteg Bridge in Munich

Building contractor:

Federal Capital of Munich

Building construction:

Mayerhofer Hoch-, Tief- und Ingenieurbau GmbH

The loop-shaped ramp is supported by six two-armed and one three-armed prop. The length of both arms varies depending on the position close to the bridge or the curve area.

Meanwhile, concreting has been finished on the south ramp. Preparations for formwork work on the even more complex, spiral-shaped northern access ramp are already underway – again, it will be a collaboration between Mayerhofer and Doka.

This might also be of interest to you

Doka Xpress CEU 02/2019

Formwork facing from the 3D printer

An extraordinary solution for a very special staircase. Read all about how a very special formwork facing was produced with the help of 3D printing systems.

Doka Xpress CEU 02/2019

A heavy weight moved with air-cushion technology

Want to know how we moved a 39.5 t supporting frame without wheel-sets? Come along and be surprised how and, most importantly, how quickly experienced construction site crew can do this.

Doka Xpress 02/2019: The 3 phases to fair-faced concrete success

Phase 1: Building planning

Fair-faced concrete is very popular. Read why it is important to get everyone involved in fair-faced concrete projects to the planning table right from the outset.