Контроль бетону

з Concremote*Фактичне відображення може відрізнятися від наведеної ілюстрації.

Concremote використовує датчики для вимірювання температури та обчислює міцність бетонної конструкції на стиск. Плануйте будівельні процеси наперед і підвищуйте свою продуктивність.

Широкий вибір багатозадачних датчиків для усіх видів проєктів, у поєднанні з потужним програмним забезпеченням слугують ідеальною основою для прийняття рішень на будівельному майданчику. Наш мобільний додаток та веб-портал надають дані в режимі реального часу та з широким спектром функцій.

![Concremote - Економія часу]()

Економія часу ![Concremote - Підвищення рівня безпеки]()

Підвищення рівня безпеки ![Зменшення викидів CO2]()

Зменшення викидів CO2 ![Concremote - Покращення якості бетону]()

Покращення якості бетону ![Concremote - Зниження витрат]()

Зниження витрат

Сфери застосування

![Моніторинг температури]()

Моніторинг температури в масивному бетонуванні

Переваги:

- Вища якість бетону

- Менше пошкоджень конструкції

- Документування всіх даних

- Значна економія завдяки зменшенню витрат на ремонт та запобігання тріщин

![Concremote | Моніторинг ранньої міцності на стиск]()

Моніторинг ранньої міцності на стиск

Переваги:

- Зменшення тривалості циклу, зокрема при використанні низьковуглецевого бетону

- Скорочення часу виконання проєкту

- Спільні рішення на основі фактичних даних

- Документування всіх даних

- Виконання важливих циклів обробки тільки з достатнім запасом міцності

- Визначений термін процесу затвердіння бетону

- Нижчі накладні витрати, пов'язані зі зменшенням часом будівництва

- Заощадження за рахунок оптимізації ціни бетонної суміші

![Concremote | Проекти з облицювання бетону]()

Проєкти з облицювання бетону

Переваги:

- Раніший процес розпалубки завдяки прогнозам щодо міцності

- Впевненість у прийнятті рішень

- Вища ймовірність досягнення однакового відтінку кольору бетону

- Уникнення витрат на ремонтні роботи з бетону

Сенсори

Цифрові сенсори Concremote безперервно вимірюють температуру і передають дані по бездротовому зв'язку через 2G, 3G, 4G або Bluetooth BLE. Потім у хмарному сховищі Concremote розраховується приріст міцності бетону, а доступ до цих даних можна отримати через веб-портал або застосунок.

Сенсор Перекриття 2.0

![Сенсор Перекриття 2.0]()

Сенсор Перекриття 2.0 - пристрій, що поєднує в собі чутливий елемент і бездротовий передавальний блок.

Він розміщується поверх бетону і може багаторазово використовуватися.Сфери застосування:

- Монолітна бетонна плита

- Прорізний тунель

- Міст

Кабельний Сенсор 2.0 з додатковим приладдям

![Кабельний датчик 2.0 з настінним сенсорним блоком]()

Настінний сенсорний блок можна встановити на будь-яку опалубку, а кабельний сенсор 2.0 передаватиме дані до хмари.

![Кабельний сенсор 2.0 з мультисенсорним кабелем]()

Мультисенсорний кабель точно вимірює температуру всередині бетону, а кабельний сенсор 2.0 передає дані у хмару.

Сфери застосування:

- Опалубка для стін і колон

- Верхолазні проєкти

- Будівництво мостів і тунелів

- Масивні бетонні конструкції

- Проєкти з облицьованого бетону

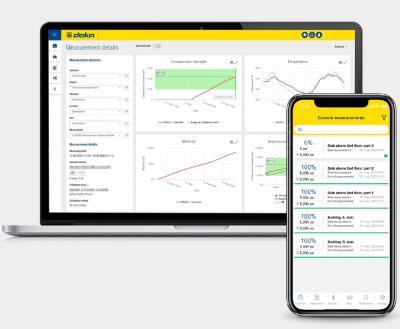

Програмне забезпечення Concremote

![Веб-портал та Застосунок]()

Веб-портал та застосунок

Переваги:

- За допомогою функції Порівняння сценаріїв можна порівнювати різні бетонні суміші, аби обрати найбільш економічну та сталу суміш для майбутніх етапів заливки.

- Надійна інформація доступна на будь-якому пристрої в режимі реального часу.

- Push-сповіщенняінформують користувача, коли бетон досягає заданої міцності або перевищує температурні межі.

- Функція прогнозу дозволяє передбачити розвиток міцності на стиск бетону і, отже, дає змогу краще планувати майбутні завдання.

- Усі результати вимірювань фіксуються, надаючи фактичні дані (звіти) для підтримки рішень при виконанні робіт на важливих етапах (розпалубка, стягування, підйом, застигання) в найкоротші терміни.

Історії успіху

Виклики, що стоять сьогодні перед будівельною галуззю, є багатогранними і змушують нас переосмислювати традиційні практики та шукати нові способи роботи. Серед цих викликів помітно виділяються три ключові аспекти: недостатня продуктивність, попит на стійкі низьковуглецеві бетонні рішення та постійний дефіцит кваліфікованої робочої сили.

Перегляньте наші історії успіху та дізнайтеся, як наші клієнти впоралися з цими проблемами, використовуючи Concremote, та навіть значно покращили результати своїх проєктів.

Сталий розвиток у бетонному будівництві

Потреба в більш екологічних бетонних сумішах

Суспільство має сильний запит на більш екологічний підхід до бетонної промисловості як такої. Цей розвиток змушує галузь переосмислювати себе та впроваджувати глобальні зміни в матеріалах, типах цементу, бетонних сумішей та методів будівництва.

Щоб успішно замінити традиційні підходи альтернативними, галузь повинна подолати певні проблеми, такі як нижчі показники міцності на ранніх етапах, більші витрати, невизначеність, і все ж таки знайти оптимізовану бетонну суміш для конкретних вимог.

Як працювати з бетонними сумішами зі зниженим вмістом CO2

Оптимізація бетонних сумішей

для зниження викидів CO2Калібрування Concremote:

Обладнання, програмне забезпечення та зворотній зв'язок допомагають у визначенні та оптимізації властивостей бетонних сумішей на ранніх етапах зі зниженим вмістом CO2.

Підвищення продуктивності на будівельному майданчику за допомогою бетонних сумішей зі зниженим вмістом CO2

Моніторинг Concremote:

Сенсори та програмне забезпечення допомагають відстежувати ранній розвиток міцності бетонних сумішей зі зниженим вмістом CO2 на будівельних майданчиках або на заводах збірних конструкцій.

Контакти

Зацікавлені у використанні Concremote на вашому наступному будівельному проєкті? Зв'яжіться з нашими фахівцями!

Документи та завантаження

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

Результати не знайдено.