Concrete monitoring

with Concremote*The actual display may differ from the illustration shown here.

Concremote uses sensors to measure the temperature and calculates compressive strength of the concrete structure. Think construction processes forward and boost your productivity.

A selection of sensors suitable for the different challenges of all types of projects in combination with a powerful software solution serve as an ideal basis for decisions on the construction site. Our native app and web portal provide real-time data and extensive functions.

![Concremote - Save time]()

Save time ![Concremote - Increase safety]()

Increase safety ![Reduce CO2 footprint]()

Reduce CO2 footprint ![Concremote - Enhance quality]()

Enhance concrete quality ![Concremote - Reduce costs]()

Reduce costs

Fields of application

![Temperature monitoring]()

Temperature monitoring in mass concrete

Benefits:

- Higher concrete quality

- Less damage to structure

- Documentation of all "as built" data

- Significant savings due to reduced crack repair & maintenance

![Concremote | Monitoring of early-age compressive strength]()

Monitoring of early-age compressive strength

Benefits:

- Shorten cycle times, in particular when utilising low-carbon concrete

- Reduce project completion time

- Collaborative decisions based on real-time data

- Documentation of all "as built" data

- Critical operations only with sufficient strength

- Determined time for curing operations

- Lower overhead costs related to construction time

- Savings by concrete mix optimisations

![Concremote | Fair-faced concrete projects]()

Fair-faced concrete projects

Benefits:

- Stripping at the earliest time thanks to the strength forecast

- "Peace of mind" in decision-making

- Higher probability of reaching a similar concrete colour tone

- Avoidance of costs for concrete repair works

Sensors

Concremote digital sensors continuously measure temperature and transmit data wireless via 2G, 3G, 4G, or Bluetooth BLE. The concrete‘s strength gain is then calculated in the Concremote cloud, and the data can be accessed via web portal or native app.

Slab sensor 2.0

![Slab sensor 2.0]()

The slab sensor 2.0 combines the sensing element and wireless transmitting unit in one device.

It is placed on top of the concrete and can be fully reused.Fields of application:

- CIP concrete slab

- Cut-and-cover tunnel

- Bridge

Cable sensor 2.0 with accessories

![Cable sensor 2.0 with wall sensing unit]()

The wall sensing unit can be installed in any formwork and the cable sensor 2.0 transmits the data wirelessly to the cloud.

![Cable sensor 2.0 with multi-sensor cable]()

The multi-sensor cable accurately measures the temperature inside the concrete and the cable sensor 2.0 transmits the data wirelessly to the cloud.

Fields of application:

- Wall and column formwork

- Climbing projects

- Bridge and tunnel building sites

- Mass concrete structures

- Fair-faced concrete projects

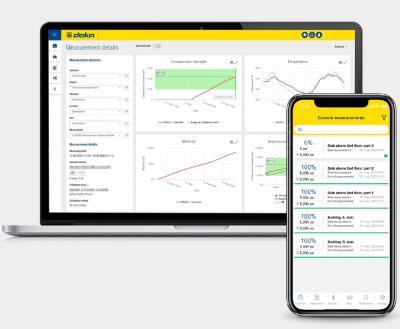

Concremote Software

![Web portal & Native app]()

Web portal & native app

Advantages:

- With the Scenario Comparison feature different concrete mixes can be compared, which allows us to choose the most economic and sustainable mix for upcoming casting steps.

- Reliable information is available on any device in real time.

- Push notifications inform the user when the concrete reaches the target strength or exceeds temperature limits.

- The Forecast feature allows to predict compressive strength development and therefore enables a better planning of upcoming tasks.

- All measurement results are logged, providing hard data (reports) to support decisions in executing critical path activities (stripping, post-tensioning, climbing, curing) at the earliest possible time.

Success stories

The challenges facing the construction industry today are multifaceted, compelling us to rethink traditional practices and explore new ways of working. Among these challenges, three key imperatives stand out prominently: the lack of productivity, the demand for sustainable low-carbon concrete solutions, and the ever-persistent skilled labor shortage.

Look at our success stories to find out how our customers dealt with the challenges they had to face by using Concremote and thus improved the outcome of their projects.

Sustainability in concrete construction

The need for more sustainable concrete mixes

Society has a strong demand for a more sustainable approach of the concrete industry as such. This development is forcing the industry to reinvent itself and implement global changes in materials, cement types, concrete mixes and construction methods.

To successfully replace traditional approaches with alternatives, the industry must overcome certain challenges such as lower early age strength-performance, cost pressure, uncertainty, and still find the optimised concrete mix for specific requirements.

How to work with CO2-reduced concrete mixes.

Optimising concrete mixes for lower

CO2-emissionsConcrete Calibration:

Equipment, software and support help in determining and optimising the early age properties of CO2-reduced concrete mixes.

Increasing productivity on the jobsite with CO2-reduced concrete mixes

Concremote Monitoring:

Sensors and software help monitoring the early age strength development of CO2-reduced concrete mixes on jobsites or in precast factories.

Contact

Interested in using Concremote on your next construction project? Get in touch with our experts!

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.