![Icon Stations and lines]()

Stations and lines

![Icon Mining method]()

Mining method

![Icon Cut-and-cover method]()

Cut-and-cover method

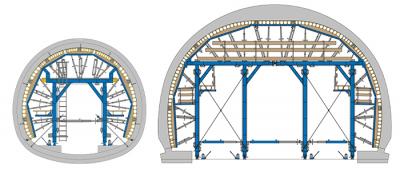

- Many system components are rentable

- Adaptability and re-usability of the systems

- System beams, walings and struts can be arranged in variable configurations, so optimum use is made of each item of equipment

- With integrated working platforms and ladderways adapted to site specifics

- Clearly structured documentation from assembly drawings through to risk assessment

- Depending on requirements, anything from a simple repositioning solution to all-hydraulic operation

- Smooth construction progress

- Optional: Short set-up times, because components of formwork and load-bearing systems are pre-assembled

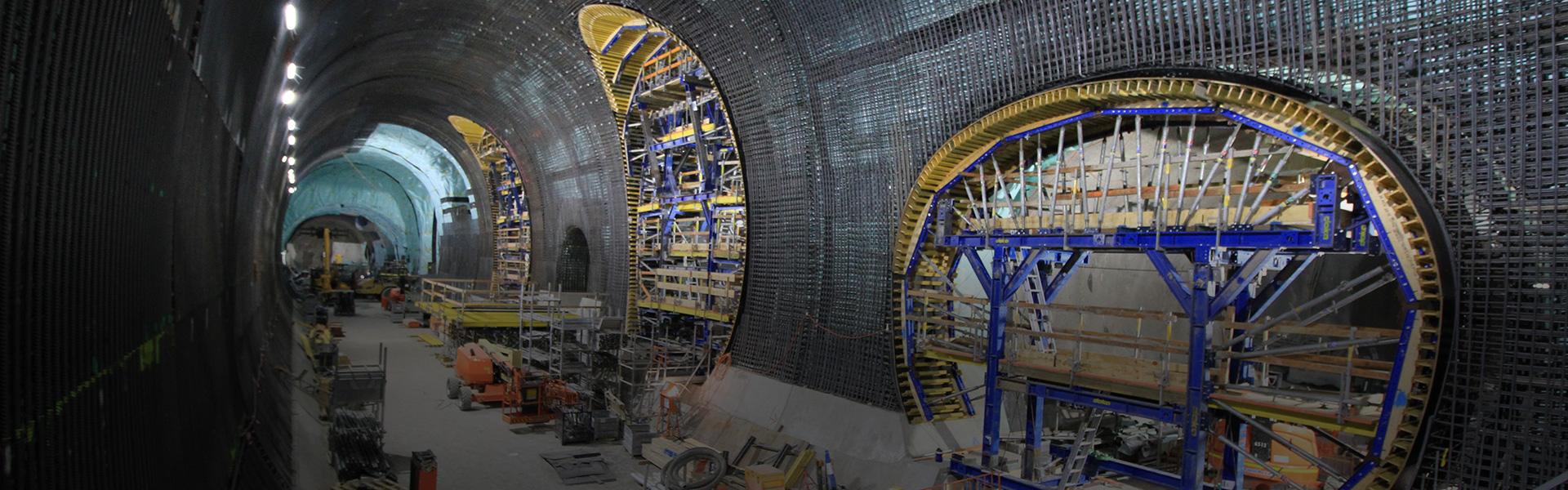

Formwork and expertise from a single source

Doka is your full-service partner on complex tunnel projects – from planning through project management to solutions that work – everything from a single source.

Economical tunnelling

Because many standard system components are rentable

![Formwork and expertise from a single source]()

![Quickly available and smooth progress]()

Quickly available and smooth progress

Because system set-up is logical with standard system parts and pre-assembly

Operation as option

Customer requirements and project needs differ, so the system comes in different configurations – from basic to all-hydraulic fully automated operation.

![Operation as option]()

![Optimierter Materialeinsatz]()

Optimised equipment usage

Modular system components adaptable to complex project geometries

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.