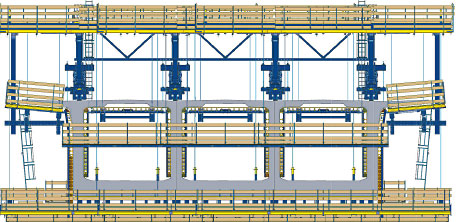

Cantilever forming traveler

Formwork and shoring from one single supplier

Modular design concept

based on rentable system components

for flexible adaptation to

- straight, sloping and multi-cell box girder cross-sections

- differing inside and outside box-girder dimensions

- non-uniformly dimensioned bottom slabs

- cantilever slabs of varying inclinations and sizes

Guaranteed to be more cost-efficient

as it is a perfectly harmonized all-in-one solution

High cost-certainty

- because the equipment is rentable, so no pre-financing is needed

- because the system components are available very quickly, meaning short delivery times

- because you do not need to maintain and store formwork equipment of your own, as the system is rentable

- because the use of standard system components means highly efficient planning

Smooth project progress

with no time-wasting, costly downtimes

Greater efficiency, as

- the planning interface with the designer of the superstructure is optimized

- both the CFT and the formwork are from the same single-source supplier

- there is an optimum design match between the traveler and the formwork

High level of ergonomic engineering

combined with a controlled construction sequence

Faster working is ensured by

- the ergonomically optimized access to all work-zones

- the ingeniously thought-out solutions for making work easier, right down to the last detail

- bracing located on the outside to make it easier to lift in the reinforcement steel

- optimum working conditions, thanks to raised longitudinal truss

Exceedingly high active and passive safety

in every phase of the work

Site crew are given maximum protection, by

- fully railed-in working platforms on all levels

- integrated ladders, complete with ladder-cages

- the safety feature which self-locks the CFT while it is being advanced on sliding plates

![]()

With the newly developed cantilever forming traveler, the 20 ft. long deck segments of the Viaducto de Teror are being cast in a weekly cycle. The pier-heads on this technically challenging bridge project were also cast using the CFT.

References

System

Optimized longitudinal trusses

- innovative geometry in the shape of upward-extended parallelograms

- for roomy, easy-to-get-at workplaces in the cover-slab and cantilever-arm formwork zones

- with an integral ladder and catwalk

Versatile anchoring cross-beam

- The suspension rods can be positioned anywhere along the beam, providing maximum horizontal flexibility

- Asymmetrical cross-beam configurations are possible where space is constricted due to e.g. neighboring structures

- Broad working platform from which the suspension rods can be operated safely

- Pre-assembly, including of the platforms, is possible at ground level

Modular design concept

The longitudinal trusses can be variably positioned, which makes it easy to adapt the cantilever forming traveler to variable-width or multi-cell cross-sections.

Pre-assembled platform system

- with integrated ladders complete with ladder cages and self-locking manholes

- on all work-deck levels

- generously sized workplace access routes for safe, efficient working

Innovative drive unit

- permanent self-locking safety feature to guard against unwanted travelling, effective up to a 6 % longitudinal gradient

- incorrect operation of this safety feature is impossible

Bracing located on outside

makes it easier and quicker to place reinforcement steel and concrete

Suitable products

Edge protection system XP

Doka Safety Systems

This system is the universal safety solution for all edge protection needs. It works in combination …

Handrail posts

Doka Safety Systems

Doka handrail posts & clamps are a must on every site. These tried-and-tested systems give your site…

Ladder System XS

Doka Safety Systems

System-based ladders can be attached to Doka wall and column formwork in a few simple steps. These s…

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.