Load-bearing tower Staxo 100

The high-capacity, fast shoring system

Staxo 100 gives a boost to safety on your site, with its

- access - slip-resistant ladders integrated in every frame

- clear safety tie-off points built into every frame

- ability to be used as a stair tower

Benefit from the advantages of the best shoring tower on the market

- extremely high leg-load capacity of up to 22.5 kip per leg

- optimum adaptability to different layouts, floor shapes and loads

- precise height adjustment, right down to the last inch, even when under load

- ideal for short or very tall shoring-heights

Staxo 100 speeds up progress on your site with its

- small number of easy-to handle component parts

- integrated couplers, no loose nuts or bolts

- integrated safety solutions

- gang ability to fly entire pre-assembled units with one pick into place

- easy repositioning on wheels or by crane

![]()

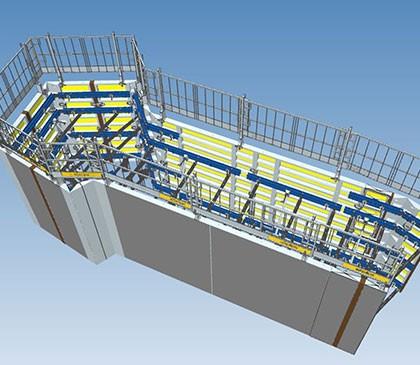

With Florida’s power need growing at a rate of 1,000-MW per year, Florida Power and Light decided to build a new 2,400-MW, natural gas fired power plant in Palm Beach County. The steam turbine pedestal that was to be constructed in less than a year would be the first “G” class three-on-one combined cycle in the nation. The key to success was finding forming solutions that would aid construction of the project’s complex pedestal featuring a 40-foot tall, 10-foot thick slab sitting on eight piers and one shear wall, while spanning over a base mat with two different elevations. Doka’s new Staxo 100 load bearing towers were the choice for the necessary shoring to support the table formwork for the towers. In all, approximately 236,000 cubic feet of shoring was used to support a table area of 8,000 square feet.

References

System

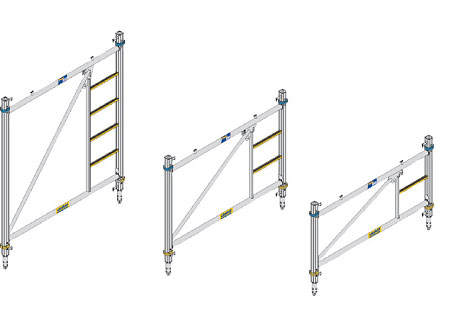

Staxo 100 frames

- extremely sturdy steel frames with heights of 3'-0" (0.90 m), 4'-0" (1.20 m) or 6'-0" (1.80 m) for easy height adjustment

- integrated connector components for easy, toolless assembly

- gravity catches for mounting the diagonal crosses quickly and safely

- integral ladder with slip-resistant ladder rungs

- defined tie-off points for personal fall arrest systems

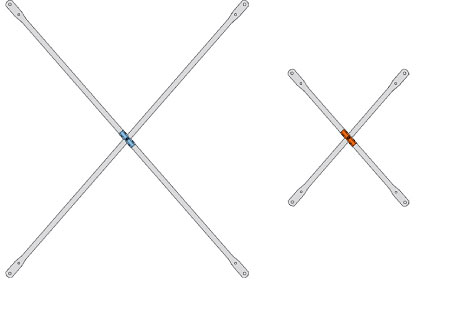

Diagonal crosses

- firmly connected diagonal braces are quick and easy to mount

- different lengths of diagonal cross permit flexible frame spacing, for optimizing the load capacity (1'-10" to 9'-10")

- unmistakable length identification provided by color-coded clips and embossed markings

Top and bottom screw-jacks

- height adjustment possible right down to the last inch

- easy to operate, thanks to special thread geometry and integrated handles

- can be released with minimal physical effort, even when under high load

Heavy duty screw jacks

The screw-jack extension length of up to 4'-8" per load-bearing tower permits optimum adaptation and adjustment for down turn beams, sloping and stepping slabs.

Utilisation

Flexible height adjustment

- using the easy-to-operate screw-jack heads and feet for continuous adjustment, with fraction of an inch accuracy, even under high load

Added single legs

- For greater horizontal flexibility

- The ideal way of adapting to any structure geometry

- Continuous positioning possible up to 5' - 0'' away from the tower

- Optimized equipment utilization

Maximum Safety

Erecting and dismantling procedures, that meet OSHA requirements

- access - slip-resistant ladder rungs integrated in every frame

- clear safety tie-off points built into every frame

Simple, fast vertical stacking

- as there are only a small number of different parts, which makes for easier handling

- as the connection sleeves and connecting pins are all integrated into the frames

- thanks to the logical erection sequence

- as the diagonal crosses are all clearly and unmistakably identified with color-coded clips

Assembly

Setting the next lift is always quick and safe.

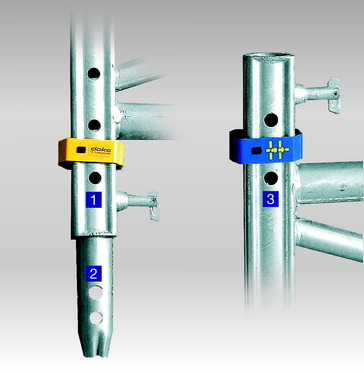

- no time lost looking for parts, because the locking springs (1), (3) and couplers (2) are captive, integrated into the frames

- only a few individual parts, they are all lightweight and easy to handle, a major benefit for anyone working high above the ground

Stair tower

Safe access to elevated workplaces by combining standard Staxo 100 frames and pre-assembled aluminum stairway treads

Erecting towers using a telescoping fork truck

This is the most efficient and safest method for erecting and dismantling towers in the upright, and for repositioning the towers

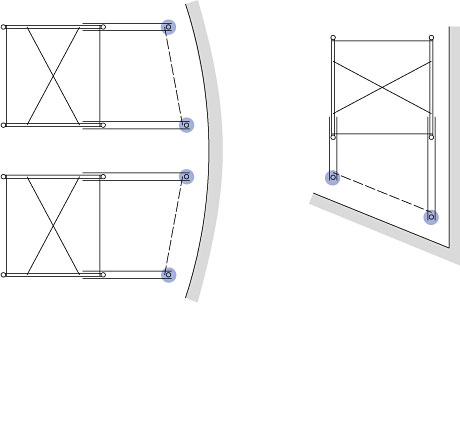

Adaptation to unusual layouts

by combining the towers with single legs

Vertical top down assembly

with an option of ganging towers and setting by crane or handsetting one at a time by man

Fast, safe repositioning

using winches, Shifting carriages TG or forklift

Horizontal assembly

a safe, fast method of erecting the towers

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.