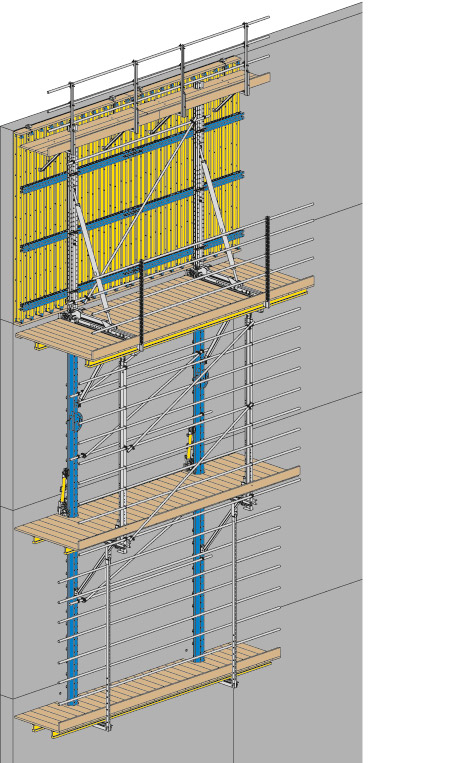

Hydraulic climbing formwork Xclimb 60

The all-round self-climbing system for use in building construction

Benefit from the system's multi-use capability

- for walls, for facades or as a protection screen

- from the option of lifting the system either by crane or as a self-climbed system using hydraulic lifting appliances

- variable platforms that allow perfect adaptation to the geometry of the structure

Safety is built in to all phases of the work, as

- the guided repositioning operation can be climbed independent of weather conditions

- enclosures can easily be constructed with materials that are adapted to the requirements

- the platforms are sized to the ideal width for practical working

- the Ladder system XS can easily be integrated into the system

Save time and money because of

- the high degree of pre-assembly possible

- its capability for fast operations

- the option to leave service loads in place on the platforms even while these are being repositioned

![site picture of SkyVue Observation wheel]()

The SkyVue Observation wheel is held upright by a pair of 274-foot cast-in-place columns that will act like bicycle forks. The 9-foot by 15-foot columns are hollow with internal stairwells that double as service access shafts. The outside forms are supported by guided climbing systems Xclimb 60, anchored to the concrete at all times. The amount of formwork used for two columns pouring concurrently is 2,492 square feet. The sequencing of each 16' lift is to pour, retract exterior forms, and then climb with guided Xclimb 60 brackets.

References

System

Hydraulic climbing formwork Xclimb 60

The system is self-climbed up to the next casting section using portable hydraulic components. Finishing-work platforms can be attached anywhere on the scaffold.

Simply self-climbing

Lightweight, quick-mount hydraulic cylinders with a lifting mechanism reliably push up the entire climbing scaffold – complete with the formwork – until the next climbing cam is pushed past the guiding shoe and automatically latches into it. To do this, each hydraulic cylinder is simply placed onto the respective guided shoe.

Outstanding workplace safety

Integral ladders and manholes provide safe access routes between the working platforms.

Utilisation

Easy to get right the first time

The Xclimb 60 system is so user-friendly that after a brief familiarization phase supervised by a Doka site foreman, the site crew quickly understand and can then work entirely independently on their own.

Protection screen Xclimb 60

To keep workers and pedestrians safe in busy downtown Toronto, Doka’s Protection Screen provides perimeter protection for the working floor and three floors below, and allows sections to fold down allowing large tables to fly in or out.

Shangri-La Hotel, Hardwall Construction, Ltd., Toronto, ON

Suitable Products

Application Videos

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.